In the rapidly evolving field of manufacturing and surface engineering, the importance of effective Laser Surface Preparation cannot be overstated. As industries increasingly seek enhanced efficiency and quality in their production processes, the optimization of laser techniques has emerged as a pivotal area of focus. Dr. Emily Chen, a prominent expert in laser technologies, once noted, "The success of any surface treatment lies in the precision of its preparation; laser surface preparation is at the forefront of this transformation." Her insights highlight the critical role that advanced laser methods play in ensuring superior adhesion, improved surface characteristics, and greater longevity of products across various sectors.

As we move toward 2025, the need for optimizing laser surface preparation techniques has become even more pronounced. Companies are tasked with not only improving their processes but also adapting to new materials and increasingly stringent quality standards. The integration of innovative laser technologies can provide manufacturers with a competitive edge, setting a foundation for better performance and enhanced product reliability. Understanding the best practices in Laser Surface Preparation will be essential in achieving these goals, making it a key topic for research and development in the years to come.

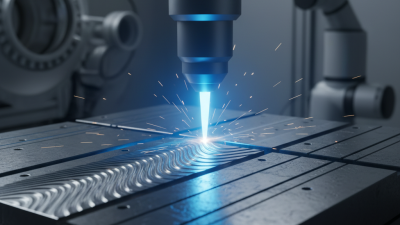

Laser surface preparation techniques have emerged as vital processes in various industries, enhancing the performance and durability of components. These techniques utilize high-intensity laser beams to clean, cut, or modify materials at the surface level, facilitating better bonding, coating adherence, and overall surface quality. A detailed overview of these technologies reveals several methods, including laser ablation, laser cleaning, and laser texturing, each with unique advantages tailored to specific applications.

When employing laser surface preparation, attention to detail is crucial. Here are some tips to optimize these techniques: First, ensure the correct choice of laser parameters such as wavelength, intensity, and pulse duration, which significantly affect the outcome of the preparation process. Second, consider the material type and composition, as different materials react differently to laser treatments, influencing efficiency and effectiveness. Finally, maintaining a consistent distance between the laser source and the work surface can enhance precision and reduce the risk of thermal damage.

By understanding the nuances of laser surface preparation techniques, industries can significantly improve their processes and product quality. Emphasizing proper practices and continuous improvement can lead to exceptional results in surface finish and performance outcomes.

| Technique | Application | Advantages | Limitations |

|---|---|---|---|

| Traditional Laser Cleaning | Metal Surface Preparation | Effective rust and paint removal | May not suit delicate surfaces |

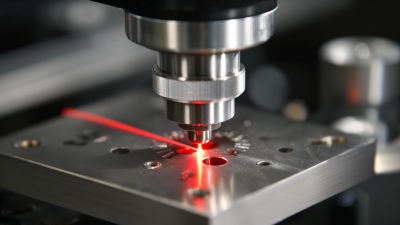

| Pulsed Laser Ablation | Surface Structuring | High precision and control | Slower processing speed |

| Laser Peening | Enhancement of Material Properties | Increased fatigue resistance | Requires specific equipment |

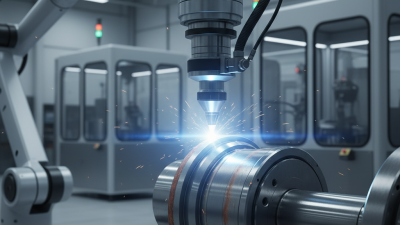

| Laser Cladding | Surface Coating | Improves wear resistance | Higher cost and complexity |

| Laser Shock Peening | Stress Improvement | Enhances material life | Requires safety precautions |

Laser surface preparation is rapidly becoming the go-to method for achieving optimal results in various industries. Compared to traditional mechanical methods, laser technology offers numerous advantages, particularly in precision and efficiency. Studies indicate that laser preparation can improve surface roughness by 50% while significantly reducing the time taken for treatment. In aerospace and automotive sectors, for instance, this translates to enhanced bonding for coatings and adhesives, leading to more robust final products.

One of the most compelling benefits of laser surface preparation is its ability to reduce contamination. Traditional methods often involve abrasive materials that can leave behind residue, while lasers can clean surfaces without introducing foreign particles. According to a report from the Society of Manufacturing Engineers, laser treatments result in lower rates of surface degradation and are less likely to affect the underlying material properties, making them ideal for high-performance applications.

Tips: When considering laser surface preparation, ensure to assess the required wavelength and energy output to match the specific material being treated. Additionally, evaluating your operational environment can optimize the effectiveness of the laser process. Finally, regular maintenance of the laser equipment will ensure consistent performance and prolong the lifespan of the technology.

The effectiveness of laser surface preparation techniques hinges on several key parameters that influence the overall results. Firstly, the selection of the laser type is crucial. Different lasers, such as fiber, CO2, or solid-state, emit distinct wavelengths and energy distributions, which can significantly affect the interaction with the material surface. The choice of wavelength influences absorption rates, thermal conductivity, and energy deposition, meaning that identifying the correct laser for the specific material and application is fundamental for optimal preparation results.

In addition to laser type, factors such as pulse duration, power density, and scanning speed play vital roles in achieving desired surface characteristics. Short pulse durations can minimize thermal damage, allowing for more precise micro-structuring, while varying power density can enhance material removal rates and surface cleanliness. Moreover, adjusting the scanning speed affects the energy input per area, impacting the depth of penetration and uniformity of the surface finish. Careful calibration of these parameters, alongside a thorough understanding of the material properties, fosters optimal laser surface preparation, yielding superior performance in subsequent applications.

This chart illustrates the key parameters influencing laser surface preparation results. The data reflects the estimated impact of various parameters on surface roughness (Ra) measured in micrometers (µm) after laser treatment.

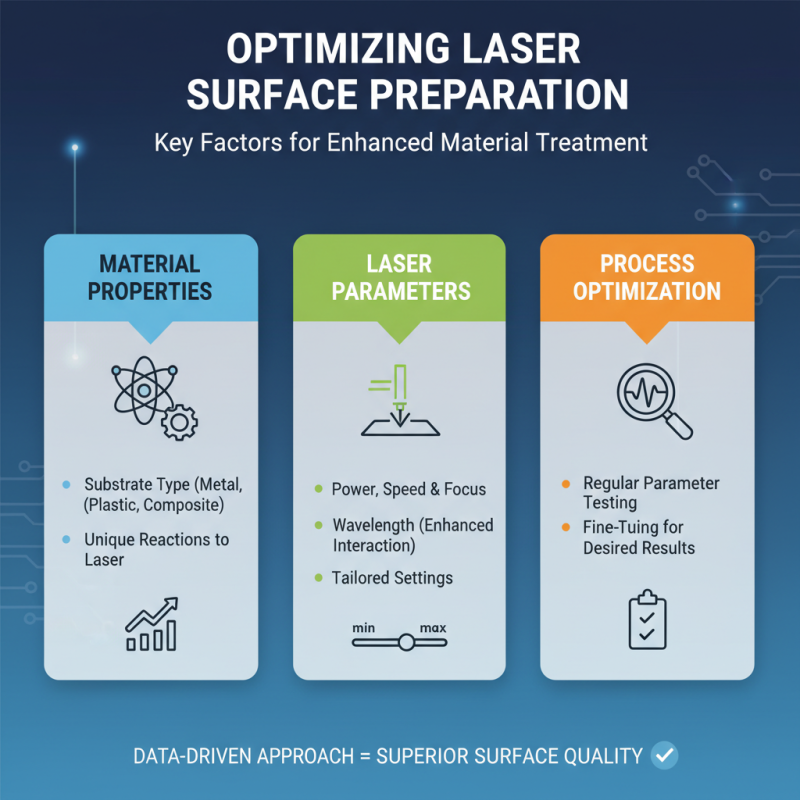

When optimizing laser surface preparation techniques, a thorough understanding of the material properties plays a crucial role. Different materials react uniquely to laser treatments, which affects cleaning efficiency and surface quality. Evaluating the substrate, whether it be metal, plastic, or composite, allows for tailored settings in terms of power, speed, and focus. Additionally, employing different laser wavelengths may enhance the interaction between the laser and the material, leading to improved outcomes. Regularly testing various parameters will help in fine-tuning the process for desirable results.

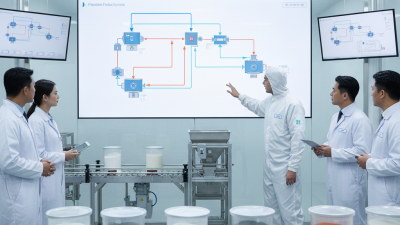

Another best practice is to ensure a clean and controlled environment. Laser surface preparation can generate debris, which could influence the quality of the surface. Implementing proper ventilation and filtration systems minimizes contamination during the process, resulting in a superior finish. Moreover, integrating automation and advanced monitoring systems enhances precision and consistency, ensuring that each cycle achieves the same high standards. Training operators on these advanced techniques fosters a better understanding of the system's capabilities, further optimizing output quality.

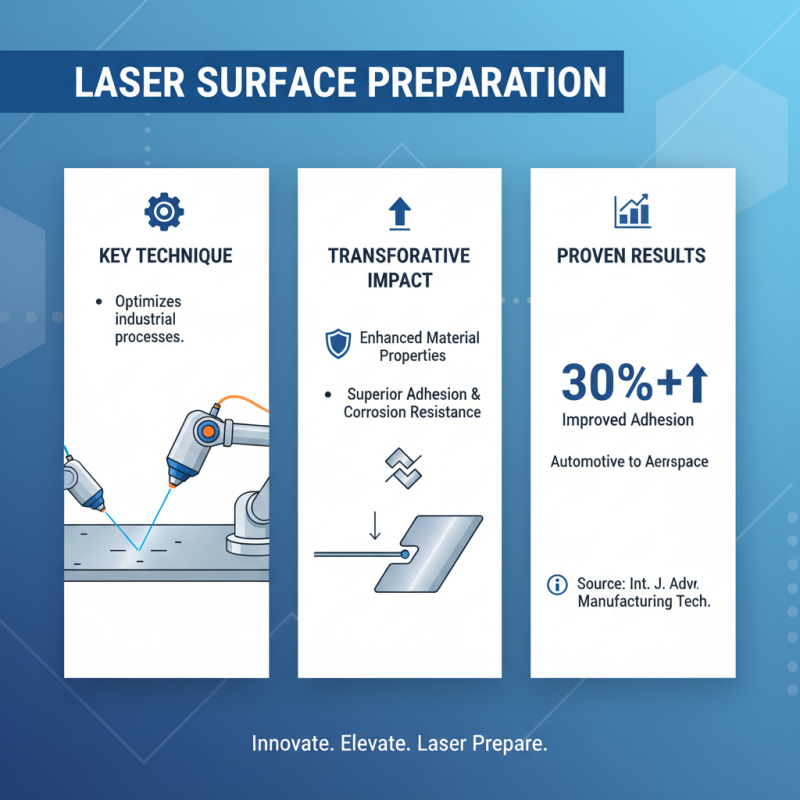

In recent years, laser surface preparation has emerged as a pivotal technique across various industries, optimizing processes and enhancing material properties. Case studies highlight the transformative impact of laser technologies on surface preparation, showcasing remarkable improvements in adhesion and corrosion resistance. According to a report from the International Journal of Advanced Manufacturing Technology, industries utilizing laser surface treatments have reported adhesion improvements of over 30%, demonstrating the effectiveness of these techniques in applications ranging from automotive to aerospace sectors.

One significant case study involves the aerospace industry, where laser surface preparation was employed to enhance the bonding of composite materials. Research presented at the 2023 Aerospace Materials Conference indicated that components treated with laser ablation showed a 50% increase in bond strength compared to traditional mechanical methods. This advancement not only reduces the risk of material failure but also extends the lifecycle of critical components, underscoring the strategic advantage of laser techniques in high-stakes environments.

Furthermore, the energy sector has seen successful applications of laser surface preparation in the refurbishment of turbine blades. A comprehensive analysis from the Energy Materials Conference revealed that laser-treated blades exhibit a reduction in surface roughness by up to 40%, leading to improved aerodynamic efficiency and enhanced operational performance. These case studies collectively emphasize the crucial role of laser surface preparation in driving efficiency and reliability across multiple industries, offering profound benefits that resonate through cost savings and enhanced material performance.