In the ever-evolving field of architecture and construction, "Cladding Operation" stands out as a critical aspect that directly influences building performance. As we look ahead to 2025, mastering the techniques of cladding operation is not just an enhancement of aesthetic appeal; it is vital for ensuring energy efficiency, sustainability, and durability of structures. Renowned cladding expert Dr. Sarah Thompson once stated, “The right cladding operation techniques can transform a building from temporary to timeless, setting a standard for energy performance and environmental responsibility."

With the increasing focus on energy-efficient designs and green building practices, understanding the intricate details of cladding operation becomes essential for architects, engineers, and builders alike. This comprehensive guide aims to delve into the various operational techniques that optimize building performance, ensuring that professionals are equipped with the necessary skills and knowledge to implement effective cladding systems. As the industry advances, adapting to new materials and methods will be crucial for aligning with emerging standards and regulations.

Ultimately, effective cladding operation is not merely a technical requirement; it serves as a foundational element that influences broader construction goals. As we explore this guide, we will provide insights into innovative practices that enhance building performance and support sustainable development—a key consideration for the future of our built environment.

Cladding plays a pivotal role in modern architecture, serving not just as an aesthetic enhancement but also as a vital component for building performance. In recent years, the emphasis on sustainability and energy efficiency has magnified the importance of cladding systems. By acting as a protective layer, cladding shields the building's structure from environmental elements while contributing to thermal insulation and energy savings. Materials such as aluminum, wood, and fiber cement have become popular choices due to their durability and minimal maintenance requirements.

Moreover, the design of cladding is integral to achieving specific architectural goals, influencing both the functionality and visual appeal of buildings. Innovations in cladding technology allow for creative freedom, where designers can experiment with various textures, colors, and patterns. Properly implemented cladding strategies can mitigate heat loss and gain, improving overall energy efficiency and occupant comfort. As the industry shifts towards more environmentally responsible practices, understanding the significance of cladding becomes essential for architects and builders committed to optimizing building performance in a rapidly evolving landscape.

The choice of materials in cladding significantly influences the overall performance of a building. Essential materials like aluminum, vinyl, wood, and fiber cement each bring unique benefits and challenges. For instance, aluminum is lightweight and highly durable, resistant to corrosion, making it an excellent choice for modern architectures that demand longevity and minimal maintenance. Vinyl, on the other hand, offers an affordable alternative with a variety of colors and styles but has limitations in terms of insulation and environmental impact.

Furthermore, wood brings a natural aesthetic appeal that many architects favor, yet it requires regular maintenance to prevent rot and damage from pests. Fiber cement stands out by mimicking wood but providing enhanced durability and resistance to fire. By understanding the properties and roles of these materials, architects and builders can make informed decisions to optimize cladding performance, enhancing both energy efficiency and building aesthetics. The right material selection not only contributes to a building’s exterior appeal but also plays a critical role in its overall sustainability and functionality.

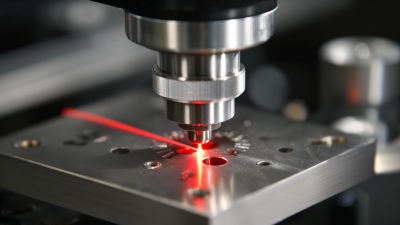

Effective cladding installation and maintenance are crucial for optimizing building performance and ensuring energy efficiency. According to a report by the Building Enclosure Council, poorly installed cladding can lead to significant heat loss, increasing energy consumption by as much as 30%. Therefore, mastering the techniques of cladding operation becomes essential for architects and contractors aiming to enhance a building’s insulation properties. Proper alignment, sealing, and drainage systems are fundamental during the installation phase to prevent moisture ingress, which can cause structural damage and mold growth.

Moreover, routine maintenance of cladding systems is vital to prolong their lifespan and maintain aesthetic appeal. The National Institute of Building Sciences indicates that regular inspections can identify early signs of wear, such as cracks or discoloration, before they escalate into costly repairs. Implementing a maintenance schedule every five years can reduce long-term operational costs by approximately 20%. By employing effective maintenance techniques, building owners can not only ensure the performance of the cladding but also contribute to sustainable building practices that align with contemporary environmental standards.

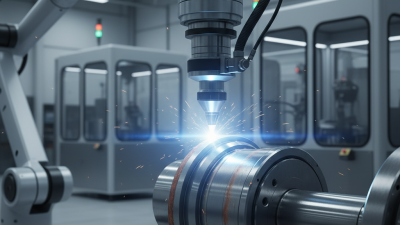

In the quest for energy efficiency in building design, innovative cladding solutions play a pivotal role. Modern cladding materials not only enhance aesthetic appeal but also significantly contribute to thermal performance. One of the foremost considerations in cladding design is the selection of materials that possess superior insulation properties. For instance, using high-performance insulated panels can reduce heat transfer and maintain comfortable indoor temperatures, thus decreasing reliance on heating and cooling systems.

Another critical aspect is the integration of sustainable practices into cladding design. Incorporating features such as green roofs, reflective surfaces, and integrated photovoltaic systems can harness natural resources while minimizing environmental impact. These innovative approaches not only help in optimizing energy use but also promote a building's longevity and resilience against climate change. By embracing such design considerations, architects and builders can create structures that not only meet aesthetic and functional demands but also contribute to a sustainable future.

This chart represents the importance rating of various design considerations for energy efficiency in cladding operations. The ratings range from 1 to 10, indicating how critical each aspect is for achieving optimal building performance.

Assessing and improving cladding longevity is crucial for enhancing building performance and reducing maintenance costs. The first step in this process involves a thorough evaluation of existing cladding materials, including their physical condition and resistance to environmental factors. Regular inspections should focus on identifying signs of wear, moisture intrusion, and thermal bridging. By employing techniques such as infrared thermography and visual assessments, building managers can detect potential issues early, allowing for timely interventions.

In addition to assessment, implementing best practices for cladding selection and maintenance is essential for longevity. Using materials that are suitable for the specific climate and environmental conditions of the building site can significantly extend the lifespan of cladding. Furthermore, regular maintenance routines, including cleaning and sealing, help prevent degradation from pollutants and weathering. By combining proactive assessment strategies with informed material choices, building owners can ensure optimal performance and durability of their cladding systems, ultimately leading to improved energy efficiency and occupant comfort.

| Cladding Type | Common Issues | Expected Lifespan (Years) | Maintenance Frequency (Years) | Improvement Techniques |

|---|---|---|---|---|

| Vinyl | Fading, Warping | 20 | 5 | Regular Cleaning, UV Resistant Coatings |

| Metal | Corrosion, Dents | 40 | 10 | Protective Coatings, Regular Inspections |

| Wood | Rot, Insect Damage | 30 | 3 | Sealing, Preservatives Application |

| Brick | Cracks, Grime Accumulation | 50 | 7 | Repointing, Power Washing |

| Stucco | Cracking, Moisture Damage | 25 | 4 | Sealing Cracks, Regular Inspections |