In the realm of manufacturing and material processing, effective surface preparation is critical for enhancing the performance and efficiency of subsequent treatments or applications. One of the most advanced methods gaining traction is Laser Surface Preparation, which utilizes high-intensity laser beams to modify the surface characteristics of various materials. This technique not only ensures superior adhesion of coatings and paints but also significantly improves the durability and overall performance of finished products.

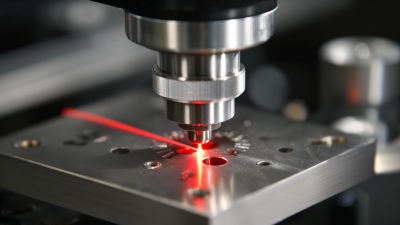

The precision and control offered by laser technology allow for the processing of complex geometries and delicate substrates, minimizing damage while maximizing effectiveness. However, achieving optimal results with Laser Surface Preparation requires a comprehensive understanding of various factors such as laser parameters, surface conditions, and material properties. By following best practices and leveraging expert tips, manufacturers can realize the full potential of laser technology, ultimately leading to enhanced product quality and operational efficiency.

As we delve into the key strategies for successful Laser Surface Preparation, it becomes clear that knowledge and preparation are paramount. From selecting the appropriate laser settings to understanding material interactions, each step plays a vital role in ensuring that the surface is meticulously prepared for the next stages of production. This guide aims to provide valuable insights and practical tips to help you harness the full capabilities of Laser Surface Preparation, paving the way for superior outcomes in your projects.

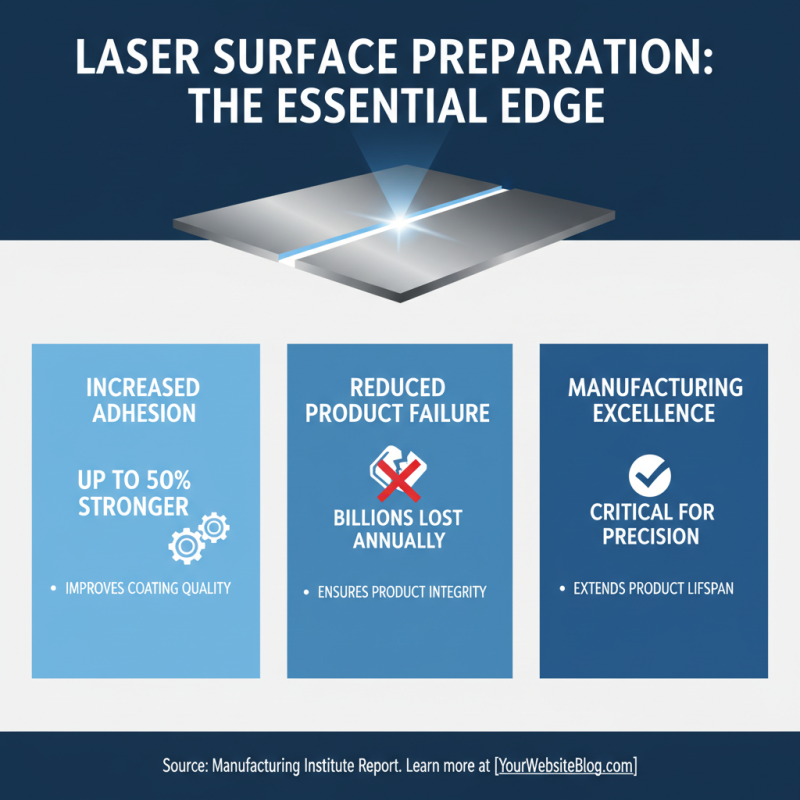

Laser surface preparation is a critical step in manufacturing processes, particularly in industries where precision and performance are paramount. Studies indicate that surface preparation can enhance adhesion by up to 50%, significantly improving the quality of coatings and treatments applied to materials. According to a recent report by the Manufacturing Institute, inadequate surface preparation is a leading cause of product failure, costing manufacturers billions annually. Therefore, implementing effective laser surface preparation techniques is essential for ensuring the integrity and longevity of products.

When preparing surfaces with lasers, it's important to follow a few best practices for optimal results. Firstly, ensure that the laser parameters, such as power and pulse duration, are correctly calibrated for the specific material type—this can prevent damage and enhance cleaning efficiency. Secondly, maintaining the right working distance between the laser and the surface can improve processing speed and finish quality, thus minimizing production time and waste. Lastly, regularly monitoring and maintaining laser equipment is crucial to sustain performance levels and reduce downtime.

By emphasizing the importance of laser surface preparation, manufacturers can not only increase product reliability but also improve overall operational efficiency. Proper surface preparation enables better adhesion, corrosion resistance, and aesthetic finishes, leading to higher customer satisfaction and reduced maintenance costs in the long run.

Effective laser surface preparation is crucial for achieving optimal performance and efficiency in various applications. This process involves several techniques that facilitate clean, precise surface finishes, ensuring better adherence of coatings and improved overall product integrity. One key technique is ensuring the right laser parameters, such as pulse duration and intensity, which can drastically influence surface quality. Proper calibration of the laser system helps in achieving uniform material removal while minimizing the risk of thermal damage to the substrate.

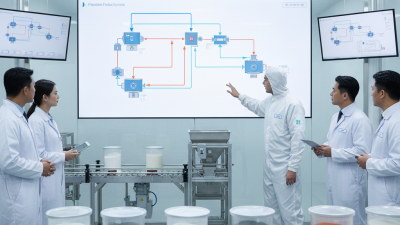

Tips for successful laser surface preparation include starting with a thorough assessment of the material properties and surface conditions. Knowing the type of substrate can guide adjustments in laser settings to optimize results. Additionally, maintaining a clean work environment is essential to prevent contamination that can compromise surface integrity. Regularly inspecting and cleaning the laser equipment itself is also critical to maintain efficiency and prolong the lifespan of the system, resulting in consistent performance.

Another effective technique involves utilizing different laser wavelengths suitable for various materials. By selecting the appropriate wavelength, practitioners can enhance energy absorption rates, leading to more effective surface modification. Incorporating automated scanning systems can improve precision and reduce processing time, ultimately increasing overall efficiency. By leveraging these techniques and tips, organizations can significantly enhance their laser surface preparation processes, leading to improved product outcomes and operational efficiency.

Laser surface preparation is a critical step in ensuring optimal performance and efficiency in various applications. However, it presents several common challenges that practitioners must navigate to achieve desired results. One primary challenge is achieving uniform surface treatment across complex geometries. Irregular shapes can create shadowing effects that prevent the laser energy from reaching certain areas, resulting in inconsistent surface quality. To overcome this, careful planning of the laser path and parameters is essential, along with potentially using multiple angles of approach to ensure complete coverage.

Another significant challenge is managing material removal rates while maintaining surface integrity. Excessive laser power can lead to unwanted thermal effects, such as warping or undesired microstructural changes in the substrate material. To mitigate this, operators must strike a delicate balance between power, speed, and focus to optimize the material removal process without compromising the underlying substrate. Proper calibration and regular monitoring of the laser system can help in fine-tuning these parameters for consistent outcomes. By addressing these factors, the efficiency of laser surface preparation can be significantly enhanced, leading to improved performance in downstream applications.

| Challenge | Tip | Potential Impact | Recommended Solutions |

|---|---|---|---|

| Inconsistent Surface Quality | Calibrate laser settings regularly | Poor adhesion and performance | Use a feedback loop for adjustments |

| Material Type Variability | Understand material properties | Inadequate removal rates | Conduct tests on sample materials |

| Laser Beam Focus | Adjust focus regularly | Uneven processing | Use beam profile monitoring tools |

| Inadequate Cleaning Process | Implement thorough pre-cleaning | Surface contamination | Use solvent solutions appropriate for surfaces |

| Operator Skill Level | Ongoing training sessions | Inefficient operations | Establish a training program with assessments |

When it comes to laser surface preparation, following best practices can significantly enhance performance and efficiency. One effective approach is to ensure that the surface is clean and free of contaminants before initiating the laser treatment. This can be achieved by employing proper cleaning techniques, such as using solvents or ultrasonic cleaning methods, depending on the material being treated. A clean surface allows for better adhesion and interaction with the laser, resulting in improved outcomes.

Another important tip is to optimize the laser parameters, such as focus, speed, and repetition rate. Conducting tests to determine the ideal settings for specific materials will help in achieving the desired surface finish without excess energy consumption. Additionally, maintaining the laser equipment in peak condition is crucial; regular maintenance and calibration can prevent performance degradation and extend the lifespan of the laser system.

Finally, it's essential to consider the environmental factors during laser surface preparation. Operating in a controlled atmosphere can minimize oxidation and other surface alterations caused by external elements, leading to a more consistent and efficient process. By adhering to these best practices, you can maximize the effectiveness of laser surface treatments and enhance overall operational efficiency.

The future of laser surface preparation technologies is on the brink of significant advancements, driven by increasing industrial demands for efficiency and precision. Recent market research indicates that the global laser surface treatment market is expected to grow at a CAGR of over 8% through 2025, reflecting a rising trend towards automated and optimized laser techniques. As industries shift towards more sustainable practices, technologies such as fiber lasers and ultrafast lasers are gaining prominence due to their ability to enhance material properties while minimizing waste and energy consumption.

In addition, integration of artificial intelligence and machine learning algorithms into laser systems is expected to revolutionize surface preparation processes. These technologies promise improved parameter optimization, allowing for real-time adjustments during treatments, which can significantly enhance product quality and reduce cycle times. Reports suggest that AI-driven laser systems could increase productivity by up to 30% in precision manufacturing applications. Furthermore, as development continues in areas such as 3D printing and material science, the interplay between these innovations and laser preparation techniques will likely pave the way for new applications, ultimately setting a new standard in the industry.