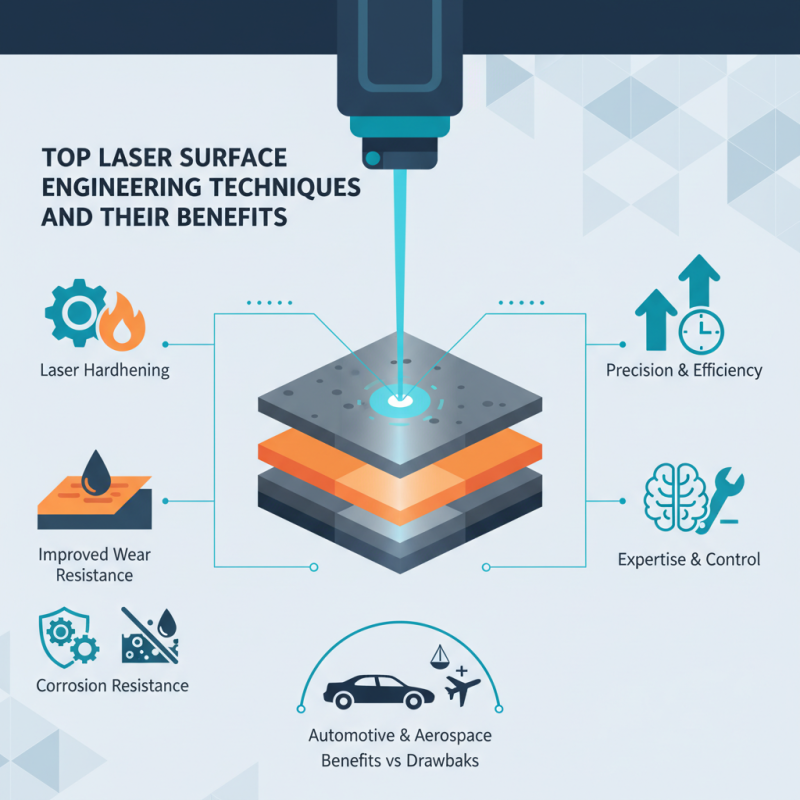

Laser Surface Engineering has transformed several industries. This technique modifies the outer layer of materials, enhancing performance and longevity. Precision and efficiency emerge as key benefits.

The various methods, such as laser hardening and laser cladding, improve wear resistance and corrosion resistance. These techniques are not without challenges. For instance, achieving the desired depth of treatment can be tricky. It requires expertise and careful control.

Many sectors, from automotive to aerospace, rely on these innovations. As technology advances, so do the possibilities. However, understanding the limitations of Laser Surface Engineering is crucial. Balancing benefits with potential drawbacks leads to better applications.

Laser surface engineering is revolutionizing industries. This method enhances material properties through precise modifications. Several techniques play critical roles in this field.

One technique is laser hardening. It improves surface hardness without altering the core properties of metals. A 2021 report indicated that laser hardening can increase wear resistance by up to 50%. However, improper parameters may lead to brittleness in certain materials. It’s crucial to find the right balance.

Another method is laser cladding. This technique adds material to surfaces, enhancing corrosion resistance and wear characteristics. Studies show that laser cladding can improve fatigue strength by approximately 30%. But the process requires meticulous control. Inconsistent practices may result in weak bonds, decreasing the effectiveness of the treatment.

These techniques offer notable benefits but also have limitations. Careful consideration is essential for optimizing outcomes.

| Technique | Description | Benefits | Applications |

|---|---|---|---|

| Laser Hardening | A technique that uses a laser to harden the surface of materials. | Improved wear resistance and extended lifespan of components. | Manufacturing, automotive, aerospace. |

| Laser Cladding | A process of adding metal material to a surface using a laser. | Restoration of worn parts and enhancement with additional material. | Repairing turbine blades, tooling, and molds. |

| Laser Engraving | Utilizes focused laser beams to engrave designs on surfaces. | Highly precise and customizable engravings. | Consumer products, jewelry, signage. |

| Laser Surface Texturing | Creates textures on the surface to enhance properties. | Increased adhesion and reduced friction. | Medical devices, automotive parts. |

| Laser Shock Peening | A method to induce compressive residual stresses in components. | Improved fatigue life and resistance to stress corrosion. | Aerospace components, pressure vessels. |

Laser surface modification involves various techniques that enhance material properties. The key principles focus on the interaction between laser light and the material's surface. When a laser beam hits a surface, it generates heat quickly. This rapid heating allows for unique changes in surface structure.

One principle is melting. Melting alters surface topography significantly. This process can improve wear resistance and reduce friction. However, precise control is crucial. Overheating can lead to unwanted defects. Another principle is alloying. By introducing new elements during the laser process, the strength and corrosion resistance of surfaces can be enhanced. This technique shows promise but requires careful calibration.

The benefits of laser surface engineering are numerous. Enhanced performance is a primary goal. Components treated with lasers often show longer lifespans. They withstand harsh environments better. Yet, the cost of equipment and expertise can be high. It’s essential to weigh these factors before adopting such techniques. Not every application may yield clear advantages, and this uncertainty requires thoughtful consideration.

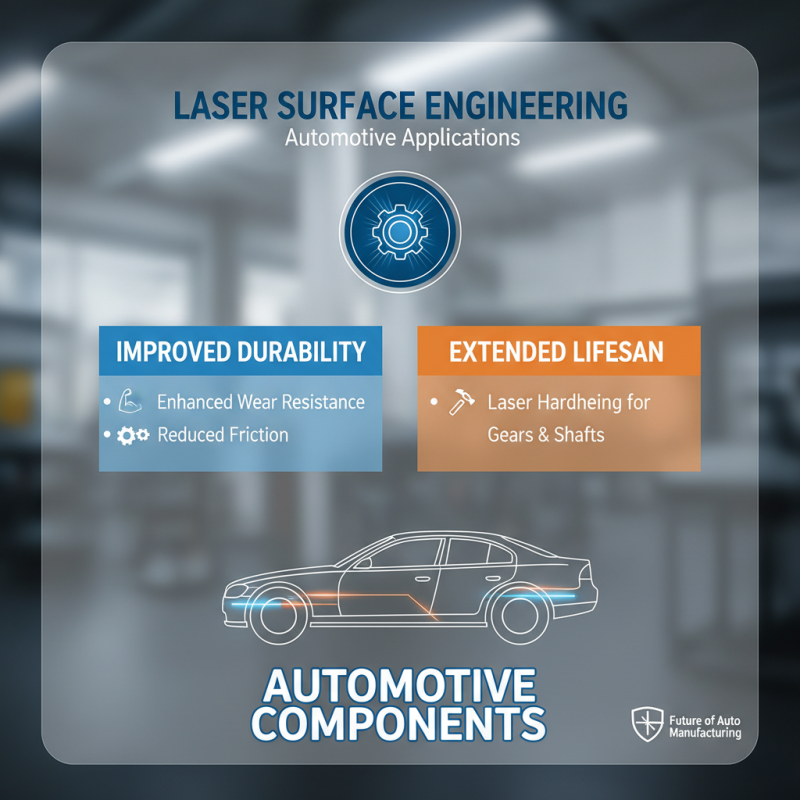

Laser surface engineering has become increasingly popular in various industries. One significant application is in the automotive sector. Laser treatment can improve the durability of car components. These treatments enhance wear resistance and reduce friction. For instance, laser hardening is a common technique used for gears and shafts. This process can extend the lifespan of critical parts.

Another notable application is in the aerospace industry. Laser surface engineering helps to improve surface properties of turbine blades. By minimizing surface defects, the efficiency of engines can be increased. This leads to better fuel economy. Furthermore, components treated with laser technology often display improved resistance to corrosion and oxidation. It has purported benefits, but the technology can be costly. Companies need to weigh the long-term advantages against the initial investment.

In the medical field, laser techniques are employed to enhance the surface of surgical instruments. This results in better performance and longevity. However, the uniformity of the treatment can sometimes be inconsistent. Some tools may show varying degrees of effectiveness. It's crucial for manufacturers to address these issues to ensure quality. Users should be aware of these nuances when selecting laser-treated products.

Laser treatment enhances the durability of materials, offering significant advantages across various industries. By focusing intense energy onto a surface, lasers create a modified layer that withstands wear and fatigue. This process can significantly increase the lifespan of components, reducing the need for frequent replacements.

One key benefit is improved resistance to corrosion and abrasion. Lasers can alter the surface properties, making materials harder and more resilient to harsh environments. Many everyday items, like tools and machinery parts, benefit from this treatment. However, not all materials respond effectively, and sometimes trial and error is necessary. Understanding which surfaces yield the best results can be challenging.

Additionally, laser surface engineering can provide a smoother finish that diminishes friction. This ensures better performance and lowers energy consumption in moving parts. Despite these advantages, the initial costs of laser systems can be high. Companies must weigh the long-term durability benefits against upfront investments. While laser treatment holds great promise, continuous evaluation and adjustment are key for achieving optimal outcomes.

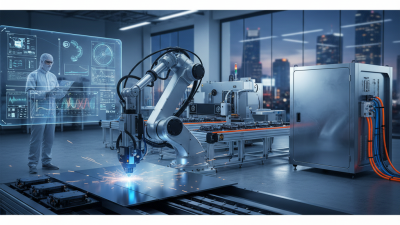

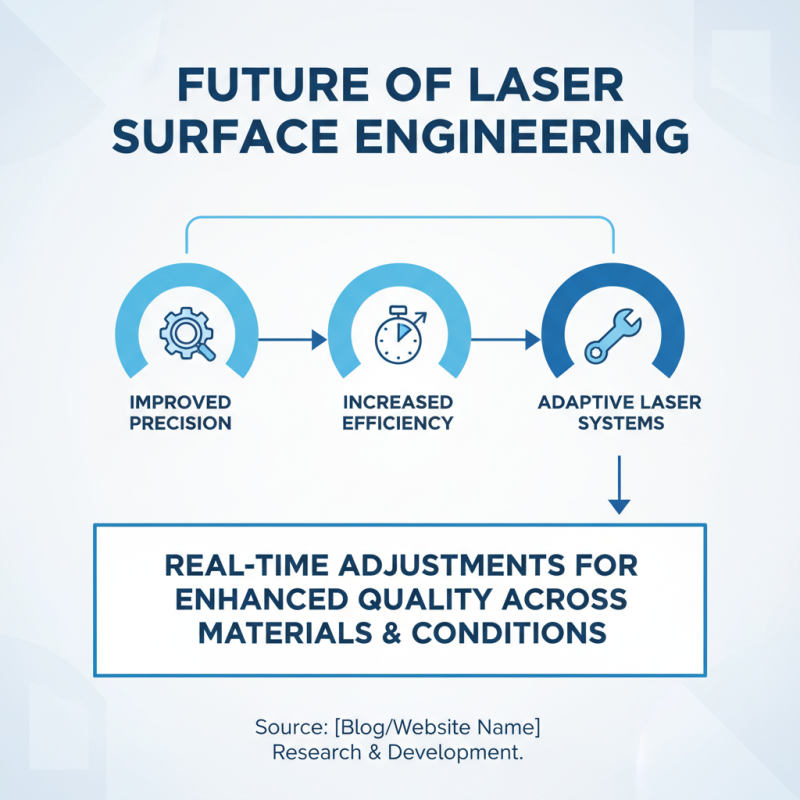

Laser surface engineering is evolving rapidly. Future trends focus on improving precision and efficiency in applications. Adaptive laser systems will likely lead the way. These systems can adjust in real-time, responding to various materials and conditions. This flexibility could enhance the quality of finishes.

Additionally, integrating AI with laser technology is an exciting prospect. AI can optimize parameters, reducing trial and error. This could streamline processes in manufacturing. However, it raises questions. How much do we trust machines to make critical decisions?

Moreover, eco-friendly practices are gaining traction. Sustainable methods may reshape the industry. Laser techniques can minimize waste and energy use. But, are we doing enough to prioritize environmental impact?