Laser Cladding Powder plays a crucial role in enhancing surface properties. Selecting the right powder can significantly improve performance. Different powders serve various applications, making the choice essential for success.

Understanding the specific characteristics of Laser Cladding Powder is fundamental. Powders vary in composition, particle size, and flowability. These factors influence the deposition process and the final product’s properties.

However, challenges exist. Not every powder suits every task. Often, users must experiment to find the best match for their applications. This reflective process can be time-consuming, yet it is necessary for optimal results.

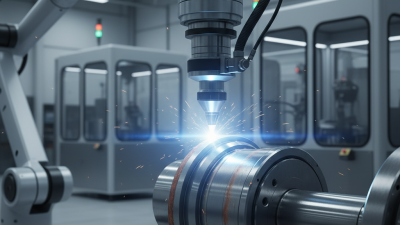

Laser cladding is a sophisticated process. It involves adding a layer of material onto a substrate using a laser. The technology is widely used in industries requiring high durability and corrosion resistance. Applications include aerospace, automotive, and oil and gas sectors. Many components need resurfacing, and laser cladding provides an effective solution.

Understanding the dynamics of laser cladding can be complex. Each application demands specific techniques and materials. The laser’s focus and speed must match the material type. This ensures a strong bond and optimal performance. However, mistakes happen. Sometimes, improper settings lead to defects in the coating. These issues need addressing before they become costly problems.

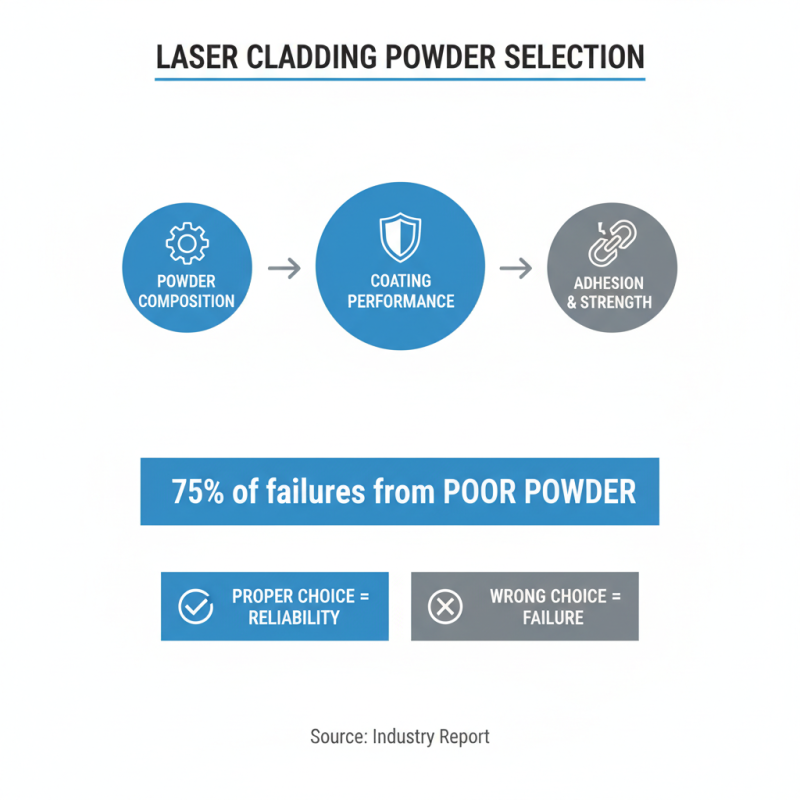

Choosing the right powder is critical. Different powders offer varied properties in terms of hardness and wear resistance. The selection process often requires experimentation. It’s essential to evaluate how the coating performs under real-world conditions. Sometimes, the results can be surprising, revealing weaknesses in seemingly standard materials. The pursuit of improvement must be ongoing. Each project provides valuable lessons for future endeavors.

This chart illustrates the performance ratings of various laser cladding powders based on their material properties. Each material's performance is rated on a scale from 1 to 10, showcasing the optimal performance of Material C at 9, while Material D underperformed with a rating of 5.

Choosing the right powder for laser cladding is crucial for performance. The composition of the powder affects adhesion, strength, and overall coating quality. According to a recent industry report, 75% of cladding failures are linked to poor powder selection. This highlights how significant proper choices are in the cladding process.

Particle size is a key factor. Powders too fine may produce excessive spatter. Conversely, powders that are too coarse can lead to poor melting. Research indicates that an optimal particle size range is 20 to 50 micrometers. This range improves flowability and enhances melting efficiency. Likewise, alloy composition plays a critical role. For instance, nickel-based powders are ideal for high-temperature applications.

It's essential to consider the application environment. Environmental conditions like humidity can impact powder performance, leading to clumping. This is a factor that shouldn't be overlooked. Many in the industry fail to test the powder under actual conditions. Some operators assume all powders perform equally. However, differing melting points significantly alter results. Taking time to choose the right powder pays off in improved performance and fewer failures.

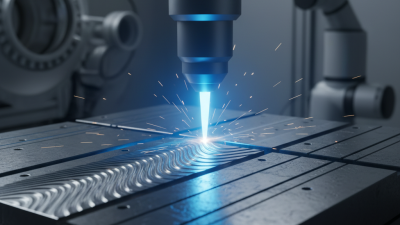

Laser cladding involves the application of powdered materials to a substrate using a high-energy laser. The type of powder used can drastically influence the performance of the process. Various laser cladding powders exist, each with unique characteristics. Common materials include stainless steel, cobalt alloy, and carbide blends. For instance, stainless steel powders provide excellent corrosion resistance, while cobalt alloys are known for their wear resistance.

Recent studies indicate that the particle size of powder plays a critical role in the cladding's microstructure. Fine powders often lead to better coverage and coherence. A report suggests that powders ranging from 15 to 45 microns show optimal results in achieving a smooth cladding layer. However, a challenge arises when using too fine powders, as they may lead to poor flow properties. Balancing these characteristics is vital.

In terms of application, the choice of powder needs careful consideration. Not all powders perform well under the same laser parameters. For instance, carbide powders might require higher energy densities. An investigation noted that the energy input can particularly affect the hardness of the cladded layer. Data reveals varying hardness values depending on powder type and laser settings. The relationship between these variables requires further exploration to enhance reliability and performance in actual applications.

| Powder Type | Material Composition | Particle Size (μm) | Application | Notes on Performance |

|---|---|---|---|---|

| Stainless Steel | Fe-Cr-Ni alloy | 30-45 | Corrosion resistance applications | Good weldability, moderate wear resistance |

| Cobalt-Based | Co-Cr alloy | 20-36 | Hard facing and wear resistance | Excellent wear resistance, suitable for high temperatures |

| Nickel-Based | Ni-Cr alloy | 15-30 | High-temperature and corrosion applications | Superior oxidation resistance, good ductility |

| Alumina | Al2O3 | 30-50 | Wear and thermal resistance | High hardness, low thermal conductivity |

| Titanium Alloy | Ti-Al-V | 20-40 | Aerospace and automotive | Lightweight, excellent strength-to-weight ratio |

Laser cladding technology has gained traction in various industries for surface enhancement and repair applications. Achieving optimal performance requires selecting the right powder. According to a report from the International Journal of Advanced Manufacturing Technology, the chemical composition of the powder significantly influences bonding strength and wear resistance.

In practice, maintaining the correct powder particle size is crucial. Ideally, it should be within 30 to 80 microns. This range ensures better flowability and more efficient melting during the laser process. However, during trials, many users note inconsistencies in powder behavior, leading to uneven coatings. Frequent adjustments in parameters such as laser power and speed are often necessary, revealing areas where process stability could be improved.

Temperature control is another critical factor. A study by the Materials Research Institute highlighted that temperature variations can cause defects like porosity and cracks. Operators need to closely monitor these conditions to maintain quality. Even experienced technicians can overlook these details, leading to subpar results. achieving optimal performance in laser cladding is not just about choosing the right powder; it also involves careful attention to the entire process.

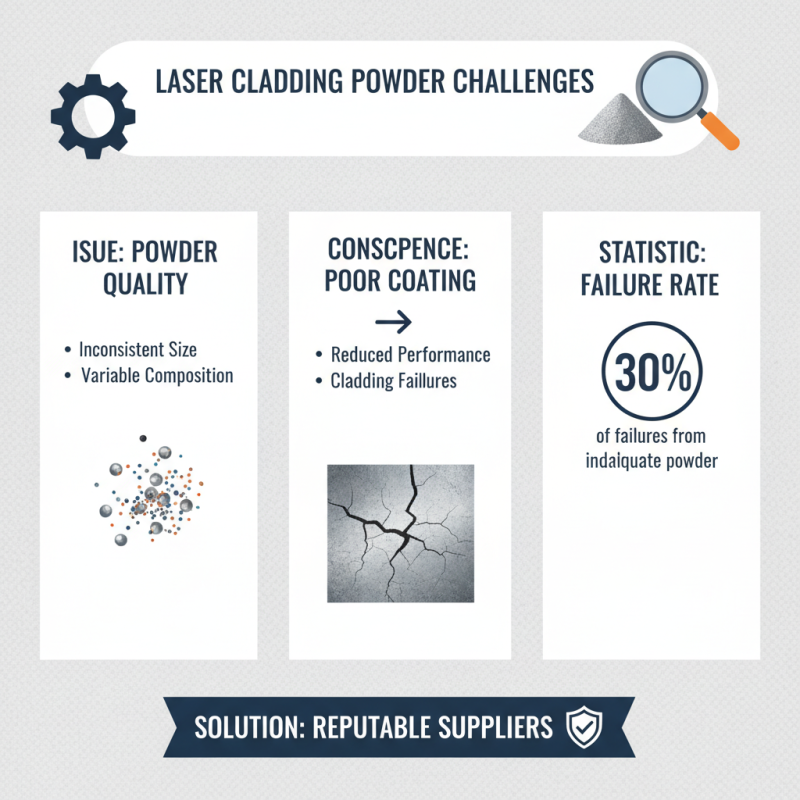

Laser cladding powder technology faces significant challenges. One of the most common issues is powder quality. Inconsistencies in size and composition can lead to poor coating properties. A study found that up to 30% of cladding failures stem from inadequate powder quality. This suggests that sourcing from reputable suppliers is crucial.

Another challenge is the control of the laser parameters. Inappropriate settings can result in defects like porosity and cracks. An ideal laser power typically ranges from 500 to 2000 watts, depending on the material. However, many operators misjudge these settings. This can lead to energy wastage and subpar results. Fine-tuning the parameters is essential for achieving desired outcomes.

Environmental factors also play a role. Humidity and temperature can affect powder performance. In high-humidity conditions, powders can clump, making them hard to use. Many industry reports note that 20% of cladding issues relate to these environmental conditions. Implementing proper storage and handling practices can mitigate these risks. It's vital to create a controlled environment for laser cladding operations.