In the evolving landscape of manufacturing and material processing, the Laser Cladding Machine has emerged as a transformative technology that offers significant benefits to businesses. With its ability to deposit materials precisely onto surfaces, this advanced technique not only enhances the performance and durability of components but also provides cost-effective solutions for repairing and maintaining critical machinery. As industries demand higher quality and efficiency, understanding how a Laser Cladding Machine operates and the advantages it brings is crucial for staying competitive.

By integrating this cutting-edge technology, companies can minimize material waste, reduce operational downtime, and extend the lifespan of their products. The versatility of the Laser Cladding Machine means it can be applied across various sectors, from aerospace to automotive, making it a valuable asset for businesses aiming to innovate and improve their processes. As we delve into the top benefits that this technology offers, it becomes clear why investing in a Laser Cladding Machine is not just an option, but a strategic move towards enhancing operational capabilities and driving business growth.

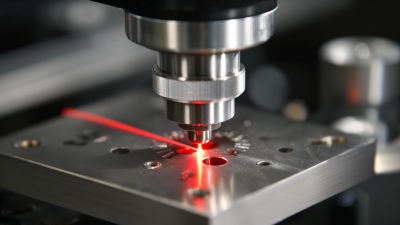

Laser cladding technology is an advanced manufacturing process that enhances the surface properties of components by precisely applying a layer of material using a high-intensity laser beam. This technique involves melting a powder or wire feedstock and depositing it onto the substrate, creating a metallurgical bond that improves wear resistance, corrosion resistance, and overall durability. The controlled nature of the laser allows for minimal heat transfer to the base material, reducing the risk of thermal distortion and ensuring a fine, high-quality surface finish.

One of the significant advantages of laser cladding is its versatility. It can be used on a variety of materials, including metals and alloys, making it suitable for various industries such as aerospace, automotive, and energy. Additionally, the process is conducive to complex geometries, allowing businesses to repair worn parts or enhance new components with tailored surface properties. By integrating laser cladding technology, companies can not only extend the lifespan of their components but also reduce downtime and costs associated with replacements, ultimately leading to improved operational efficiency.

A laser cladding machine is a sophisticated tool used to enhance the surface properties of existing components through the deposition of material. The key components of this machine include a laser source, a powder feeder, and a motion system. The laser source, often a fiber or CO2 laser, generates high-intensity beams that fuse cladding materials, typically metal powders, onto the substrate. The precision of the motion system is crucial, as it ensures consistent coverage and adherence, which is key to achieving the desired quality of the coating.

According to a recent industry report by MarketsandMarkets, the global laser cladding market is projected to grow from USD 400 million in 2020 to USD 760 million by 2025, highlighting the increasing adoption of this technology in various sectors. Businesses can leverage this growth by investing in laser cladding machines to enhance their manufacturing processes, improve the durability of components, and reduce overall maintenance costs.

**Tips:** When considering a laser cladding machine, evaluate the types of materials you frequently use in your operations. Additionally, ensure that your team undergoes adequate training to maximize the machine's capabilities and maintain safety standards during operation. Regular maintenance of the laser equipment is vital to sustain performance and quality output.

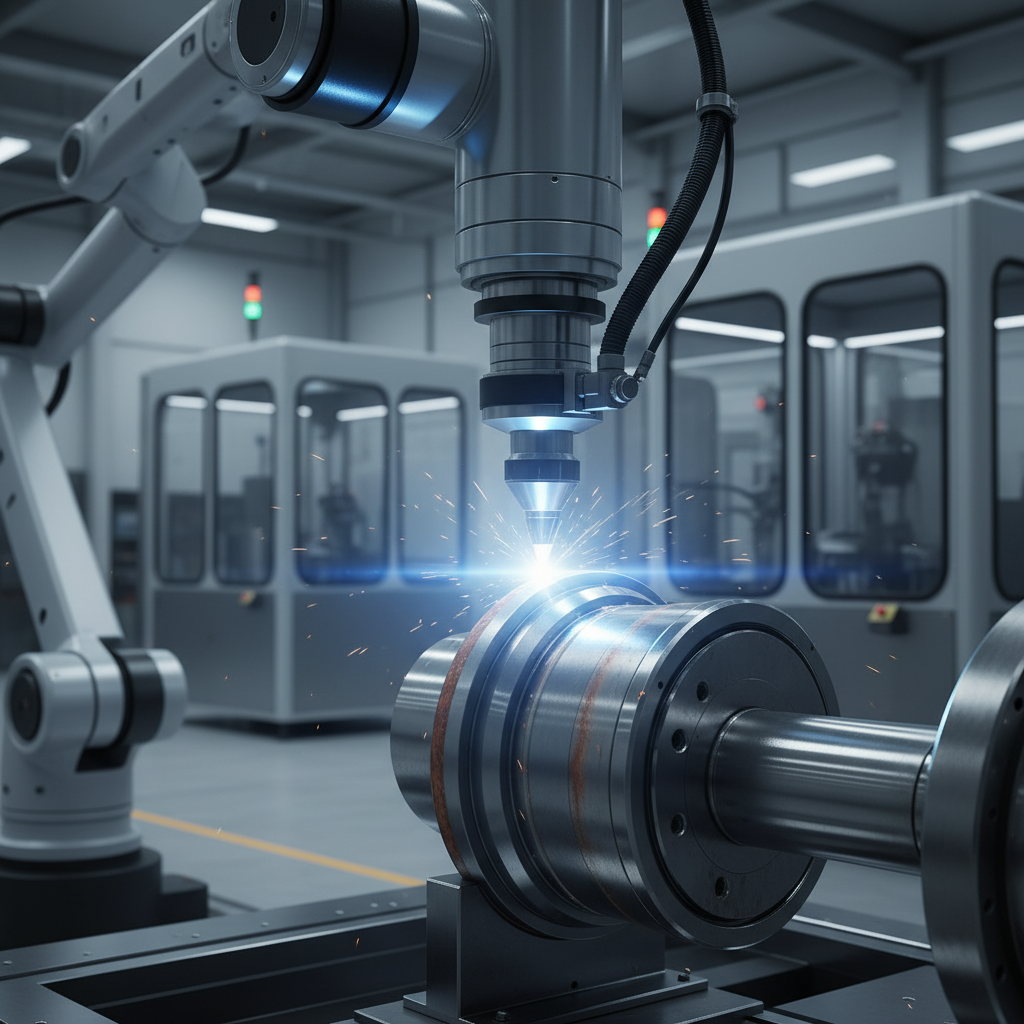

Laser cladding technology offers significant advantages for manufacturing efficiency, making it an essential tool for modern industries. By utilizing a high-powered laser to melt and fuse materials onto a substrate, businesses can enhance the surface properties of components without compromising their structural integrity. This precision allows for targeted application, minimizing waste and ensuring that only the necessary areas are treated. The ability to layer different materials means that companies can improve corrosion resistance, wear strength, and thermal conductivity, tailoring their products for specific applications.

Moreover, laser cladding can dramatically reduce lead times in the production process. Traditional methods of surface enhancement often involve extensive machining or treatments that can be time-consuming.

In contrast, laser cladding allows for rapid deposition, shortening production cycles and enabling companies to meet tight deadlines. This efficiency not only boosts productivity but also lowers operational costs by reducing the need for additional processes and materials. By integrating laser cladding into their manufacturing operations, businesses can achieve higher quality outputs while remaining competitive in an increasingly demanding market.

Laser cladding is rapidly gaining traction across a variety of industries due to its unique ability to enhance the performance and longevity of components. In the aerospace sector, for instance, a report from MarketsandMarkets estimates that the market for laser cladding will grow from USD 1.0 billion in 2021 to USD 1.8 billion by 2026, reflecting a compound annual growth rate (CAGR) of 12.3%. This growth is driven by the need for superior material properties and surface durability, which laser cladding provides by creating a metallurgical bond between the substrate and the cladding material.

The automotive industry also stands to benefit significantly from laser cladding technology. By applying this technique, manufacturers can reinforce various parts such as engine components, which can lead to increased performance and reduced wear. According to a recent analysis from Grand View Research, the automotive laser cladding market is projected to reach approximately USD 650 million by 2025, showcasing a robust demand for advanced surface enhancement solutions. Similarly, the energy sector, particularly in wind and oil & gas applications, utilizes laser cladding to combat the harsh environmental conditions that can lead to component degradation. This method ensures operational efficiency and lowers maintenance costs, making it an attractive investment for businesses striving to optimize their production processes.

The future of laser cladding technology is poised for significant advancements, driven by the increasing demands for precision and efficiency in various industrial applications. One of the most notable trends is the integration of artificial intelligence and machine learning into laser cladding systems. These technologies can enhance process control, optimize parameters in real-time, and ensure consistent quality in coatings, ultimately reducing waste and increasing productivity.

Another emerging development is the expansion of materials used in laser cladding. As industries explore new alloys and composite materials, laser cladding technology will adapt to accommodate these innovations. This versatility allows for tailored solutions that enhance component durability and performance, particularly in sectors such as aerospace and automotive, where materials must withstand extreme conditions. The continued evolution of laser cladding machines will likely include advancements in automation, leading to more streamlined operations and the possibility of remote monitoring and maintenance.