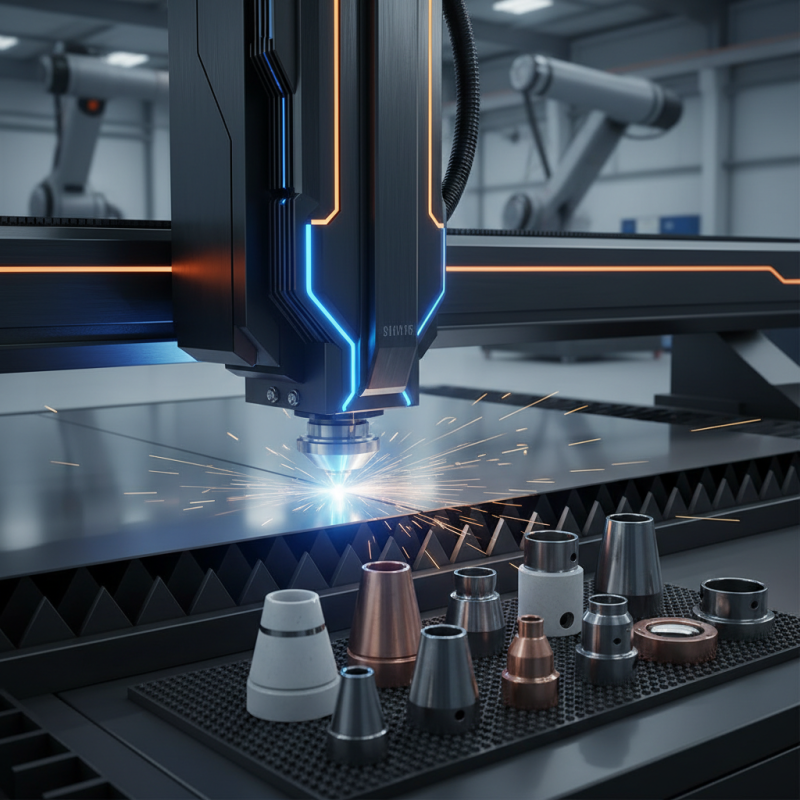

In the world of precision machining and cutting, the performance and longevity of your equipment largely depend on the components utilized, particularly the Laser Head. As technology advances, understanding the nuances of various Laser Head tips becomes essential for maximizing efficiency and output quality. This guide aims to equip users with the knowledge to select, maintain, and optimize Laser Head tips, ensuring not only superior performance but also enhanced durability over time.

Laser Head tips come in various configurations and materials, each designed for specific applications and environments. By delving into the intricacies of these tips, we can provide insights on how to choose the right one for your needs, and what factors to consider for both short-term use and long-term investment. Whether you're utilizing laser systems for cutting, engraving, or marking, mastering the use of Laser Head tips will significantly impact the overall success of your projects, making this guide an invaluable resource for operators and technicians alike.

Laser head tips play a crucial role in enhancing the performance and longevity of laser cutting and engraving systems. Different types of tips are tailored for specific materials and applications, allowing operators to achieve optimal results. For instance, conical tips are often utilized for engraving purposes, as their design facilitates better control of laser focus, enabling intricate designs on various substrates. In contrast, flat tips are preferred for cutting operations, providing a more consistent beam profile especially effective in thicker materials. According to a report by the International Laser Industry Association, employing the right tip can increase cutting speed by up to 25%, emphasizing the importance of selecting an appropriate design based on the intended use.

The choice of laser head tips also impacts the operational costs and overall efficiency of laser systems. A study from the Laser Institute of America indicated that utilizing high-quality tips tailored for specific applications can reduce maintenance frequency and enhance durability, resulting in an estimated 30% decrease in downtime. Additionally, using the correct tip helps in minimizing material wastage and improving the precision of cuts, contributing to overall cost savings in production processes. By understanding the various types of laser head tips available, operators can maximize performance while extending the lifespan of their equipment, thereby ensuring a sustainable approach to laser operations.

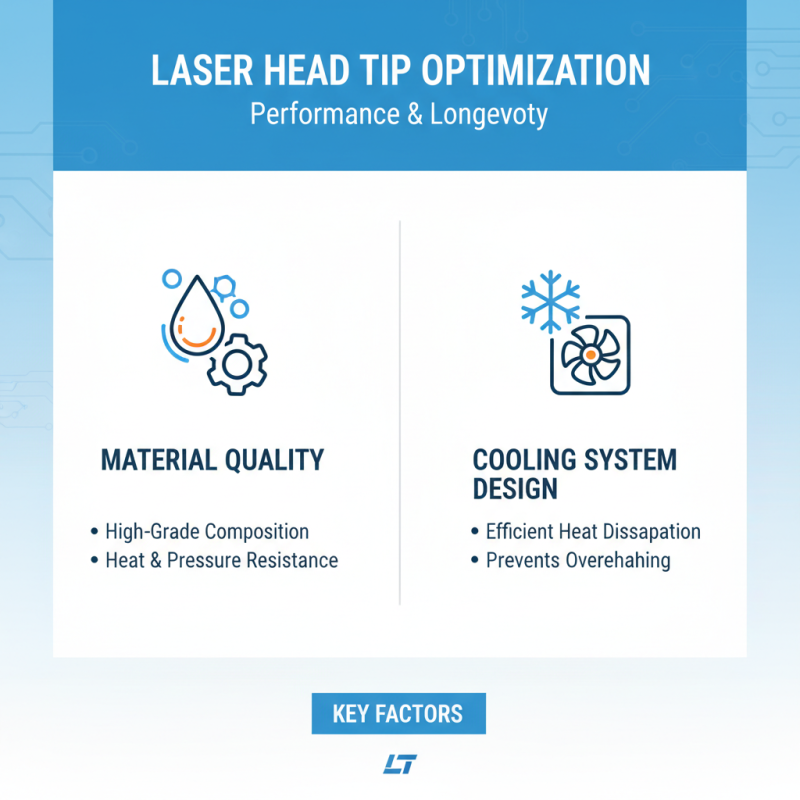

When it comes to maximizing the performance and longevity of laser head tips, several factors play crucial roles. One of the primary considerations is the quality of the materials used in manufacturing the laser head. High-grade materials can withstand higher temperatures and pressures, which can significantly reduce wear and tear during operation. Additionally, the design of the cooling system is important; effective cooling mechanisms prevent overheating, thereby protecting the laser components from damage and extending their lifespan.

Another critical factor is the operating environment in which the laser is utilized. Exposure to dust, moisture, or extreme temperatures can adversely affect the performance of the laser head. Implementing proper protective measures, such as using sealed enclosures or regular maintenance checks, can mitigate these risks. Furthermore, the operational parameters, such as the power settings and duty cycles, should be optimized. Running the laser at appropriate settings prevents unnecessary strain on the components and ensures efficient operation, contributing to both immediate performance and long-term durability.

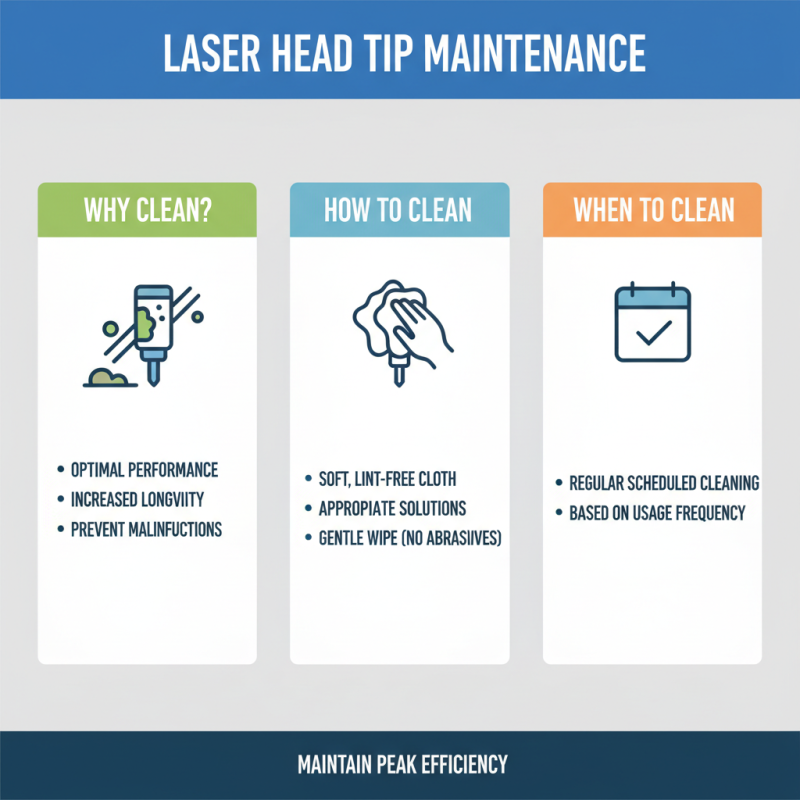

To ensure optimal performance and longevity of laser head tips, implementing a regular maintenance routine is crucial. One effective practice is to clean the laser head tips frequently. Accumulated residue can lead to inefficiencies and malfunctions. Use a soft, lint-free cloth and appropriate cleaning solutions to gently wipe the tips, ensuring that you avoid abrasive materials that might cause scratches. Regularly scheduled cleaning, varying based on usage frequency, helps maintain peak operational efficiency.

Another important tip is to inspect the alignment of the laser head tips. Misalignment can result in uneven wear and poor engraving or cutting quality. Periodically check the positioning and make necessary adjustments to ensure the laser beam is hitting its intended target accurately. Utilize alignment tools as needed and keep an eye out for any signs of wear or damage that may require further attention.

Lastly, it's essential to store laser head tips properly when not in use. Protect them from dust, moisture, and extreme temperatures, as these factors can deteriorate the tips over time. Use protective covers or cases to minimize exposure to environmental elements, and label storage containers to easily locate different tip types when needed. By observing these maintenance best practices, you can significantly enhance the lifespan and performance of your laser head tips.

When utilizing laser head tips, operators may encounter several common issues that can significantly impact performance and longevity. One prevalent problem is beam misalignment, which can lead to suboptimal cutting or engraving results. According to a report from the Laser Institute of America, nearly 30% of laser system inefficiencies stem from improper alignment of the laser heads. Regular calibration and alignment checks can help mitigate these issues, ensuring that the laser is operating at its maximum efficiency and delivering precise results.

Another frequent issue is the buildup of residue or debris on the laser tip, which can obstruct the beam and diminish performance. A study by the International Society for Optics and Photonics indicates that maintaining clean optics can improve cutting speed by up to 15% and enhance the overall quality of the output. Implementing a routine maintenance schedule, including regular cleaning of the laser head tips, can prolong their lifespan and reduce the frequency of required replacements. By addressing these common problems, users can maximize the efficiency and durability of their laser systems, ultimately leading to improved productivity and cost-effectiveness in their operations.

Upgrading laser head tips is a crucial step in enhancing the efficiency of laser systems. The right tip can significantly affect the precision and quality of the cuts or engravings produced. By selecting tips that are specifically designed for the material being worked on, users can achieve cleaner cuts and reduce the amount of post-processing required. For instance, using a tip with a suitable focal length and diameter can lead to better energy concentration, resulting in faster processing times and a smoother finish.

Furthermore, the material of the laser head tips plays a key role in their durability and performance. Opting for high-quality materials can resist wear and tear over time, ensuring that the tips maintain their shape and continue to deliver optimal results across multiple projects. Additionally, regular maintenance, including timely replacement of worn tips, can prevent unexpected downtime and promote a more efficient workflow. Investing in the right upgrades for laser head tips not only boosts performance but also enhances the longevity of the equipment, maximizing overall investment and productivity.

| Tip Type | Material | Optimal Power (W) | Optimal Speed (mm/s) | Expected Lifespan (Hours) | Cooling Type |

|---|---|---|---|---|---|

| Standard Lens | Glass | 40 | 600 | 2000 | Air Cooling |

| High-Performance Lens | ZnSe | 60 | 800 | 3000 | Liquid Cooling |

| Focus Lens | Glass | 50 | 500 | 1500 | Air Cooling |

| Reflective Mirror | Mirrored Coating | 100 | 1000 | 2500 | Air Cooling |

| Specialized Tips | Ceramic | 70 | 700 | 4000 | Liquid Cooling |