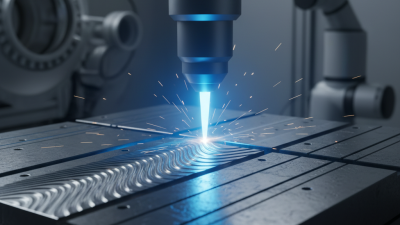

As we approach 2026, the landscape of Laser Surface Finishing is undergoing rapid evolution. Dr. Lisa Reynolds, a leading expert in the field, states, "Innovation in laser technology will redefine surface treatment processes." This sentiment captures the essence of the current trends shaping this industry.

The potential for Laser Surface Finishing is immense. From automotive parts to delicate medical devices, its applications are baffling. However, challenges remain. Not all surfaces behave the same under laser treatment. This inconsistency requires constant adjustments and learning.

Moreover, sustainability will play a crucial role in the future. The demand for eco-friendly processes is rising. Companies must adapt or risk falling behind. As industry leaders explore these trends, it's clear that while the future of Laser Surface Finishing is promising, it also demands reflection on both successes and failures.

The landscape of laser surface finishing is rapidly transforming, driven by ongoing advancements in laser technology. According to a recent market report, the laser surface finishing industry is expected to reach a value of approximately $2.5 billion by 2026, reflecting a compound annual growth rate of over 12%. This growth is largely due to the increasing demand for precision manufacturing across various sectors like aerospace and automotive.

Recent innovations include ultra-short pulse lasers that enable finer material removal with minimal heat-affected zones. This technology enhances surface quality while reducing the risk of material distortion. However, there are challenges as well. The cost of implementing advanced laser systems can be prohibitive for smaller manufacturers. Additionally, operators need extensive training to use these sophisticated tools effectively. Not every company can keep up with these advancements, which might create an uneven playing field.

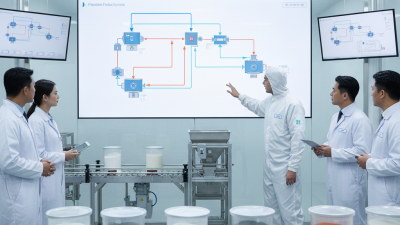

As we look toward 2026, surface finishing processes will likely incorporate more automation. AI and machine learning could optimize laser parameters in real time, improving efficiency. However, consistent quality remains a concern. The reliance on advanced technology necessitates robust quality assurance systems to ensure product standards. Companies must reflect on how they can adapt without compromising quality and accessibility in this evolving landscape.

The future of laser surface finishing is bright, with exciting applications across various industries. In automotive manufacturing, laser finishing is enhancing the durability of components. It provides a precise method to improve surface integrity, ensuring parts withstand harsh conditions better than ever. This method is especially useful for complex geometries, making it a preferred choice for innovative designs.

In the aerospace sector, laser finishing is becoming vital. It helps reduce weight while maintaining strength. Engineers are exploring its potential for turbine blades and jet engine components. This technology is still evolving, and challenges remain. Consistency in results can be a concern, and further research is needed to address these issues.

Medical devices also benefit from laser surface finishing. It ensures cleanliness and precision, which are critical in this field. However, the industry must navigate regulatory challenges. Each application presents unique hurdles. Balancing innovation with safety remains a fundamental goal. As technology advances, the quest to perfect laser finishing continues, making it an area ripe for exploration.

| Application Area | Industry | Trend Indicators | Projected Growth (%) |

|---|---|---|---|

| Surface Cleaning | Manufacturing | Increased efficiency and reduced waste | 15% |

| Coating Removal | Aerospace | Eco-friendly methods gaining traction | 20% |

| Micro-texturing | Medical Devices | Enhancements in bio-compatibility | 10% |

| Welding Preparation | Automotive | Higher quality joints with laser avant-garde | 12% |

| Surface Hardening | Tooling | Increasing durability and service life of tools | 18% |

| Polishing | Consumer Electronics | Aesthetic enhancements and surface smoothness | 15% |

As we look towards 2026, sustainability trends will significantly influence laser surface finishing practices. Companies are increasingly focusing on eco-friendly methods to reduce waste and energy consumption. This shift arises from both regulatory pressures and consumer demand for more sustainable processes. Many organizations are transitioning to renewable energy sources to power their operations. This may lower carbon footprints and operational costs.

Another important aspect is the recycling of materials used in laser surface finishing. There's a growing emphasis on using recyclable or bio-based materials in manufacturing processes. This change is not without challenges. Achieving quality results while maintaining sustainability can be complex. Some techniques may require adjustments that could impact efficiency. Industries must continuously evaluate these processes and find a balance between innovation and environmental responsibility.

Moreover, education and training about sustainable practices in laser finishing are increasingly important. Many workers are unaware of the best practices for minimizing waste. There is still a long way to go in terms of adopting these new trends comprehensively. Industry leaders need to invest in workforce development to meet these evolving standards. This investment is vital for fostering a culture of sustainability within the sector.

In 2026, the integration of AI and automation in laser surface finishing will reshape the industry. Companies are increasingly using AI algorithms to optimize processes. This technology can analyze data quickly, adjusting parameters for better outcomes. Automation will drive efficiency, reducing the need for manual interventions.

Tips: Always gather data before implementing changes. Understanding the current process is essential for improvement. Small adjustments can lead to significant gains.

As AI takes center stage, it may create challenges too. Not all surfaces will respond to automated techniques. Some materials require nuanced handling that AI can overlook. Regular training for operators is vital. They need to interpret AI insights effectively while ensuring quality remains intact.

Tips: Invest in staff training. Knowledgeable operators can bridge the gap between machines and real-world applications. Balancing technology and human intuition may lead to better results. This approach keeps operations flexible and responsive.

The landscape of laser surface finishing is evolving. As we approach 2026, several challenges emerge. One significant issue is the high initial investment and operational costs. Many businesses hesitate to adopt this technology due to budget constraints. Additionally, there's a lack of comprehensive training programs. Skilled operators are essential for maximizing efficiency. Without proper training, mistakes can lead to waste and reduced output.

On the other hand, there are opportunities ripe for exploration. The versatility of laser systems allows them to be applied in various materials. Industries are beginning to recognize this potential. Researchers are focusing on improving laser finishing techniques. Innovations can lead to faster processing times and better quality surfaces. Moreover, sustainability is becoming a priority. Eco-friendly practices in laser finishing can attract more clients. However, the balance between cost and sustainability remains a concern. More reflection on these aspects is necessary as we advance.