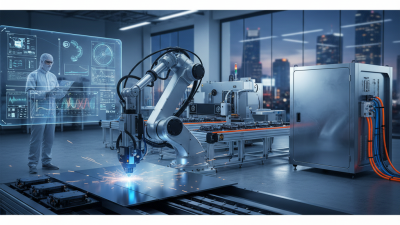

Shaft Repair is a critical aspect of maintenance in various industries, including manufacturing, mining, and energy. Properly maintained shafts can significantly enhance the overall efficiency and longevity of machinery, minimizing downtime and reducing operational costs. According to a report by the International Society of Automation, improper maintenance can contribute to up to 30% of unplanned downtime in industrial operations. Therefore, the importance of effective shaft repair and maintenance cannot be overstated; it is essential for optimizing performance and ensuring safety standards are met.

Effective shaft repair not only involves the physical restoration of components but also encompasses ongoing maintenance strategies that prevent future failures. Industry data reveals that regular maintenance can extend the lifespan of equipment by as much as 25%, highlighting the need for asset managers to prioritize shaft upkeep in their preventative strategies. By adopting essential tips and methods for shaft repair and maintenance, companies can improve their operational reliability and cost-effectiveness while mitigating risks associated with equipment failure. Therefore, understanding and implementing best practices in shaft repair is vital for maintaining competitive edge in today's industrial landscape.

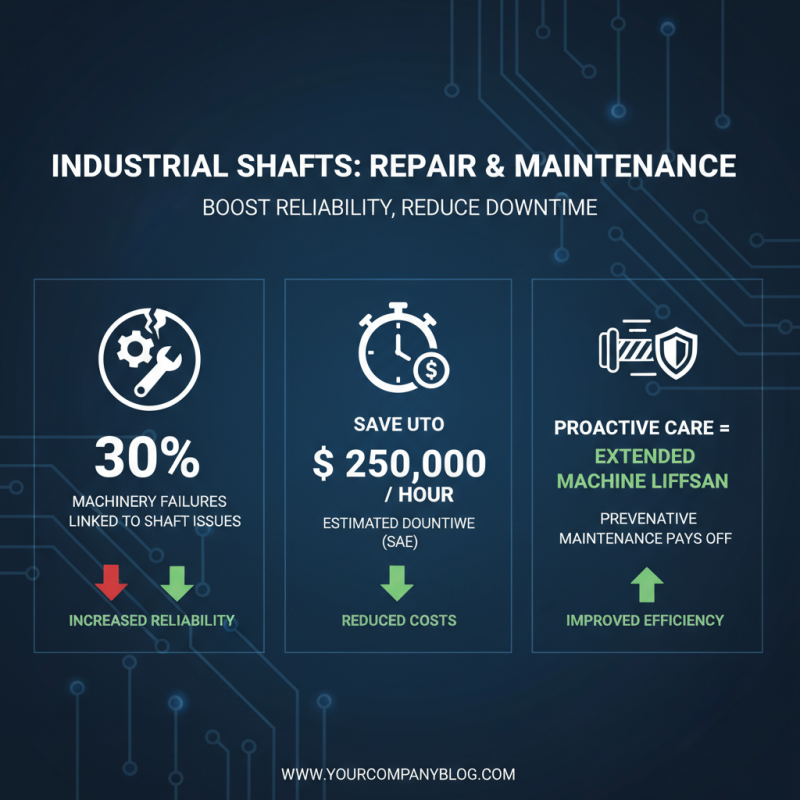

Shaft repair and maintenance play a critical role in ensuring the longevity and efficiency of machinery across various industries. Studies indicate that approximately 30% of machinery failures are linked to issues with shafts, highlighting the need for regular maintenance and timely repairs. By addressing these concerns, businesses can significantly reduce downtime and associated costs, which the Society of Automotive Engineers estimates can reach up to $250,000 per hour for large industrial operations.

Moreover, proper shaft maintenance is essential for maximizing energy efficiency. A report by the American Society of Mechanical Engineers states that unmaintained or poorly functioning shafts can lead to increased power consumption by as much as 20%. Elevating the focus on routine inspection and corrective actions not only enhances production reliability but also contributes to sustainable practices by minimizing waste and reducing energy use. Implementing a preventive maintenance strategy that prioritizes shaft integrity ultimately results in improved operational performance and a safer work environment.

Shaft damage and wear can significantly impact machinery performance, leading to costly repairs and downtime. Common causes of shaft failure include misalignment, which occurs when the shaft is not properly aligned with other connected components. This can lead to uneven stress distribution, causing premature wear and potential failure. Additionally, excessive loading due to operational overloads can exacerbate this issue, leading to bending or breaking of the shaft over time.

Another frequent cause of shaft deterioration is insufficient lubrication. Proper lubrication is crucial to minimize friction and wear between moving parts. When lubrication is inadequate or contaminated, it can lead to increased heat generation and wear on the shaft surfaces. Environmental factors, such as exposure to corrosive substances, can also contribute to shaft damage. Corrosion can weaken the material integrity, resulting in pitting and eventual failure. Regular inspections and maintenance practices are vital to identify these risks early and extend the lifespan of shafts in any mechanical system.

When it comes to maintaining the integrity of machinery, the condition of the shaft is paramount. A systematic approach to inspecting shaft condition can prevent extensive downtime and costly repairs. According to a report by the International Journal of Mechanical Engineering, improper maintenance can lead to a 30% increase in equipment failure rates. Therefore, conducting regular inspections is essential for optimal performance.

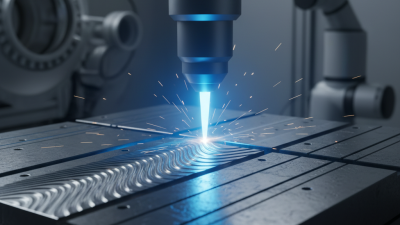

Begin by visually examining the shaft for wear signs such as scoring, pitting, or bending. This initial step helps identify any obvious flaws that may affect the shaft’s functionality. Utilizing tools like dial indicators and vibration analysis can provide quantitative measures of any deviations in shaft alignment or integrity. A study from the American Society of Mechanical Engineers highlights that early detection of wear can extend the lifespan of rotating equipment by up to 20%, underscoring the importance of precision during the inspection process.

Once potential issues are identified, take measurements of key parameters, including runout and alignment deviations. Comparing these figures against established tolerances will guide maintenance decisions. Keeping detailed records of these inspections not only aids in tracking performance trends but also contributes to a proactive maintenance strategy, allowing for better resource allocation and enhanced operational efficiency. Adhering to these inspection guidelines will not only improve shaft reliability but can also result in significant long-term savings for industrial operations.

Effective shaft cleaning and preparation are critical components in ensuring the longevity and reliability of machinery. Proper maintenance not only enhances performance but also reduces the likelihood of costly breakdowns. According to a recent industry report, neglecting regular cleaning can lead to a 25% decrease in efficiency, emphasizing the importance of incorporating best practices in shaft repair and maintenance.

One crucial tip is to use the right cleaning agents that suit the materials of the shaft. A study by the Machinery Lubrication Association highlights that using inappropriate solvents can cause surface damage, leading to premature wear. Opt for non-corrosive cleaners to protect the integrity of the shaft. Moreover, a systematic approach to cleaning—beginning with the removal of coarse debris, followed by fine cleaning using brushes or cloths—ensures a thorough job that prepares the shaft for further inspection and maintenance.

Additionally, maintaining a clean work environment significantly aids in keeping the shaft free of contaminants. Implementing a strict housekeeping protocol can enhance overall maintenance efficiency. A clean space reduces the risk of external particles damaging the shaft during handling or inspection. Regularly scheduling these cleaning tasks can improve productivity and extend the life of machinery, as indicated by ongoing maintenance studies that report a reduction in downtime by up to 30% when proper cleaning protocols are followed.

| Tip | Description | Frequency | Tools Required |

|---|---|---|---|

| 1. Inspect Regularly | Inspect shafts for signs of wear or damage. | Monthly | Visual Inspection Tools |

| 2. Clean Before Repairs | Thoroughly clean the shaft to ensure proper adhesion of repair materials. | Before Repairs | Cleaning Solvents, Brushes |

| 3. Use Proper Lubricants | Select lubricants that are compatible with shaft materials. | As Needed | Lubricants, Application Tools |

| 4. Monitor Alignment | Ensure shafts are properly aligned to prevent vibration and wear. | Quarterly | Alignment Tools, Laser Alignment Systems |

| 5. Check for Corrosion | Inspect for signs of corrosion and take corrective actions as needed. | Biannual | Corrosion Inspection Tools |

| 6. Replace Worn Seals | Replace seals when they show wear to prevent leaks. | As Needed | Seal Replacement Kits |

| 7. Document Maintenance | Keep a log of maintenance work to track history and schedules. | Ongoing | Maintenance Log Software |

| 8. Use Proper Tools | Always use the correct tools for repairs to avoid damage. | Always | Specific Hand Tools |

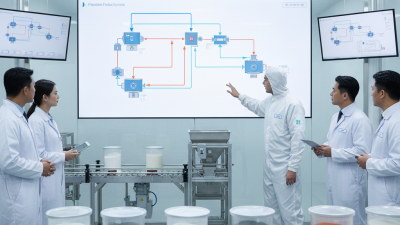

| 9. Train Staff | Ensure all personnel are trained in best maintenance practices. | Annually | Training Materials |

| 10. Schedule Regular Overhauls | Plan for routine overhauls to prevent issues from escalating. | Yearly | Service Tools |

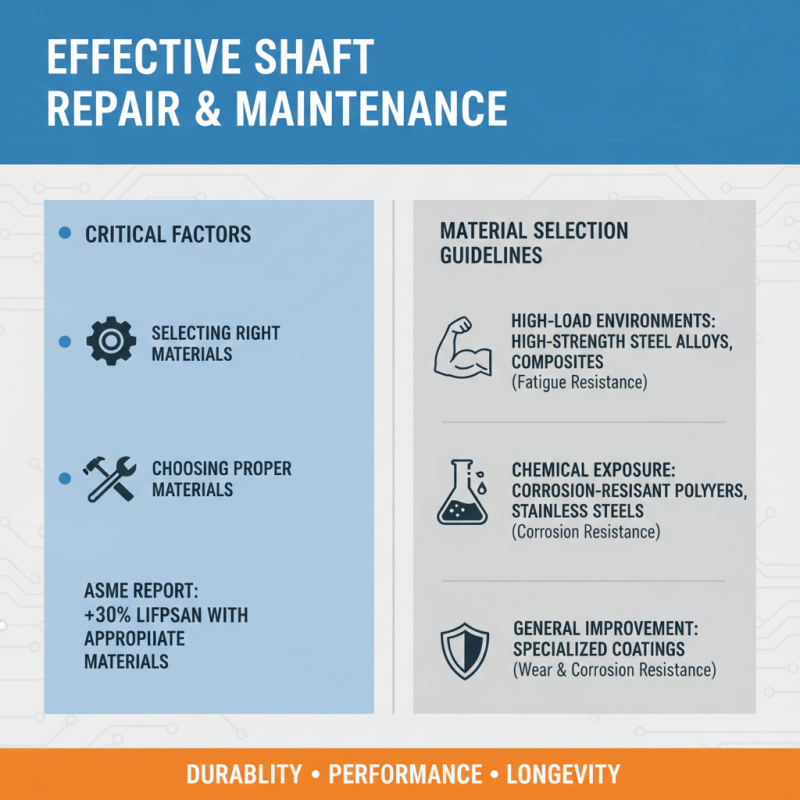

When it comes to effective shaft repair and maintenance, selecting the right materials and tools is critical to ensuring durability and performance. According to a report by the American Society of Mechanical Engineers (ASME), using appropriate materials can enhance the lifespan of repaired shafts by up to 30%. Materials such as high-strength steel alloys, composites, or specialized coatings can significantly improve resistance to wear and corrosion. For instance, shafts operating in high-load environments require materials with excellent fatigue properties, while those exposed to harsh chemical conditions should be made from corrosion-resistant polymers or stainless steels.

Equally paramount is the choice of tools for the repair process. Precision tools that ensure accurate measurements and alignments can reduce the risk of future failures. A study published in the Journal of Manufacturing Science and Engineering highlights that improper tooling can lead to an increase in repair costs by 20% due to rework and additional downtime. Utilizing technology such as laser alignment systems not only improves accuracy but also helps in the proper installation of components, contributing to overall shaft integrity. Investing in high-quality tools and materials is not just a cost consideration; it is a strategic approach to prolonging the performance and reliability of machinery, ultimately leading to increased productivity in operations.