Choosing the right Laser Lens is crucial for achieving optimal results in various applications. Expert John Smith, a renowned figure in the laser technology field, emphasizes, "A good lens can make all the difference in precision." This statement highlights the importance of understanding your specific needs when selecting a Laser Lens.

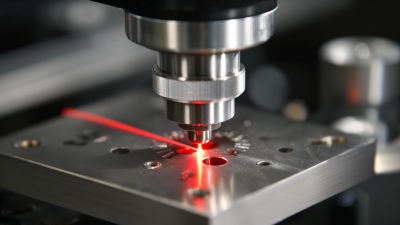

Laser Lenses come in various types and specifications. Each lens has unique properties that affect focus, clarity, and durability. For instance, a lens designed for cutting may not be suitable for engraving. It's vital to consider the material and design that matches your project requirements.

Many users overlook critical factors like wavelength compatibility and focal length. These elements directly impact the quality of the laser work being performed. A mismatch can lead to wasted materials and time. Reflecting on these choices and seeking expert advice can help avoid common pitfalls in the selection process.

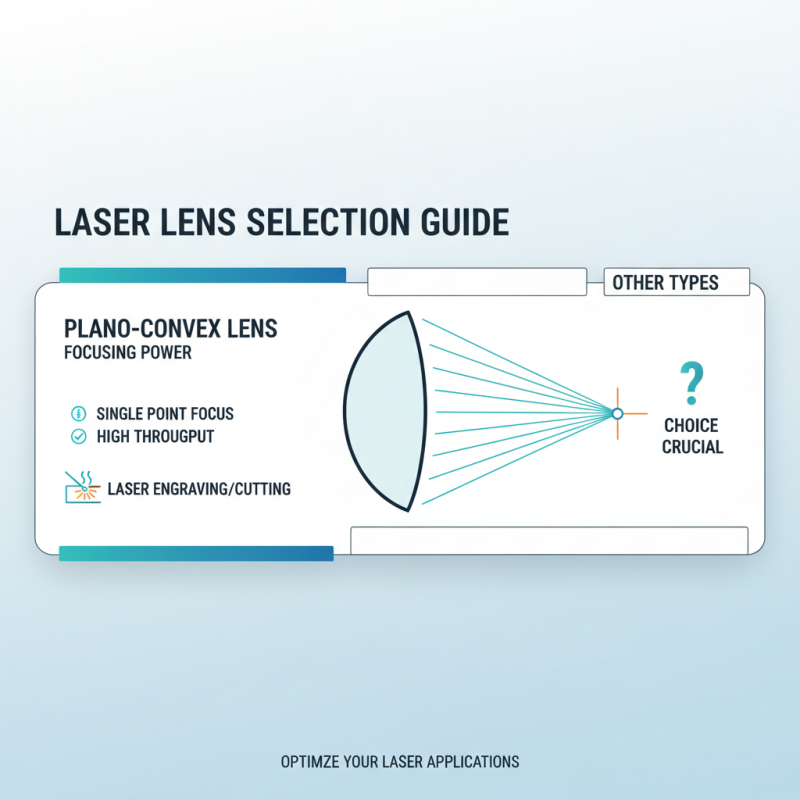

When selecting a laser lens, it's crucial to understand the different types available. One common type is the plano-convex lens. This design focuses light into a single point, making it ideal for applications like laser engraving or cutting. Its simple structure also ensures high throughput, which is essential for efficient work processes.

Another type is the aspherical lens. This lens minimizes spherical aberration, enhancing image quality. Users will often find this lens suitable for more complex tasks. However, it's important to note that aspherical lenses can be more challenging to align. Misalignment can lead to wasted materials and poor results.

Reflective lenses serve different needs, mainly in scenarios where high power is involved. They reflect rather than refract light. This efficiency can be beneficial, but the specific application needs careful consideration. A mismatch can lead to ineffective performance or damage to the system. Each lens has its unique attributes, making informed choices a vital part of the laser application.

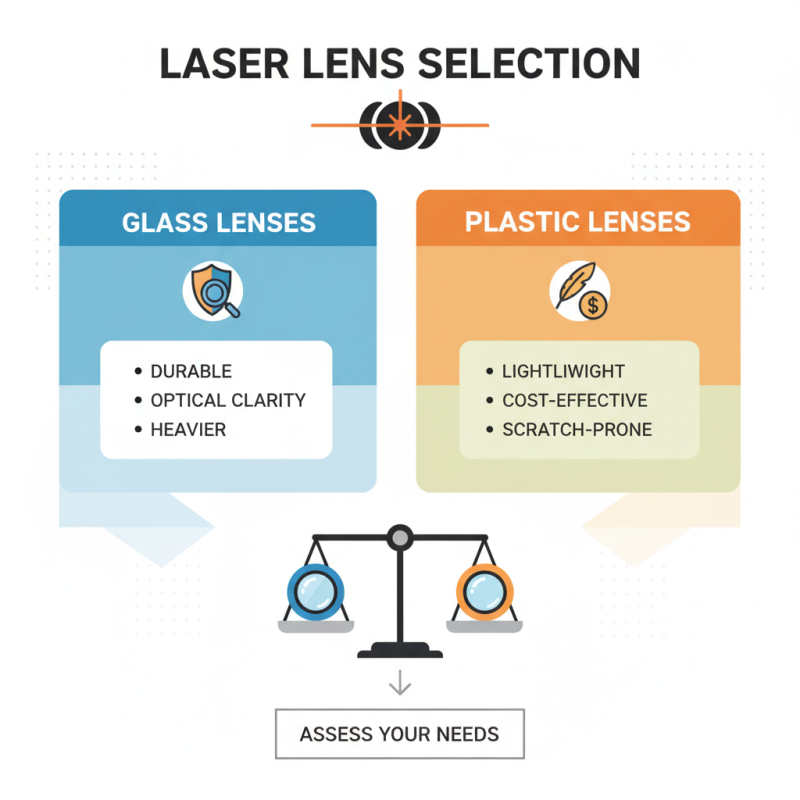

Choosing the right laser lens is crucial for optimal performance. There are key factors to consider. First, the lens material plays a significant role. Glass or plastic options each have their own benefits. Glass is often more durable, while plastic is lightweight. You should assess the specific requirements of your project before making a choice.

Next, think about the focal length. This directly affects the precision of your laser work. A shorter focal length offers tighter focus but less depth of field. On the other hand, a longer focal length provides broader coverage but less detail. It can be tricky to find the right balance here.

Consider the coating of the lens as well. Anti-reflective coatings can enhance efficiency. However, not all coatings are created equal, and some may not be suitable for high-power lasers. This can lead to reduced performance and unwanted burns. Reflect on your needs carefully to avoid these pitfalls.

Choosing the right laser lens is critical for achieving optimal performance. One essential factor is the lens material. Common options include glass and plastic. Glass offers durability and superior clarity, but it can be heavier. Plastic is lighter and often less expensive, yet it may scratch more easily. Assess your specific needs before deciding.

Coating options also play a significant role in lens performance. Anti-reflective coatings can minimize glare and enhance transmission. Certain coatings protect lenses from scratches and environmental factors. However, not all coatings perform equally; some may degrade over time. It’s essential to evaluate how these factors align with your usage.

Keep in mind, the decision process can be overwhelming. You may feel uncertain about which features are most important. Test different combinations to see what works best for you. Experimentation is key, and don't rush the decision. Opting for the right combination of material and coating can make a significant difference in your laser experience.

When selecting a laser lens, compatibility with your laser system is crucial. The lens must match the specific wavelength and focal length your setup requires. Mismatches can lead to inefficiencies and poor results. Ensure you know your laser's specifications well. This understanding helps you avoid common pitfalls.

Consider the mounting type. It should fit securely within your system. A loose fit can cause misalignment issues. This affects the quality of your work. Always double-check measurements before purchasing.

Pay attention to the lens material. Glass and plastic have different properties. Glass lenses tend to provide clearer results for high-precision tasks. However, they may be more fragile. Depending on your applications, this could be a trade-off to consider. Be mindful and reflect on what matters most for your projects.

Proper maintenance of laser lenses is crucial for achieving optimal performance. This involves regular cleaning to remove dust and debris. Use a soft, lint-free cloth for the job. Avoid harsh chemicals, as they can damage the coating. A gentle cleaning solution can be effective for stubborn spots. Remember, your technique matters. Rushing can lead to scratches.

Storage plays a significant role in lens longevity. Always keep lenses in a protective case when not in use. Temperature and humidity can affect their condition. Too much moisture can lead to mold, while extreme heat can warp the lens. It's essential to be mindful of your environment. Look for a consistent climate where you store your equipment.

Also, inspect lenses regularly for signs of wear. Small scratches can worsen over time. If you notice any imperfections, consider professional assessment. It’s not just about performance; it’s about prolonging the life of your investment. Carelessness can cost you. Reflect on your practices to ensure you're doing what’s best for your lenses.

| Tip | Description | Benefits | Maintenance Tips |

|---|---|---|---|

| 1. Determine Your Application | Understand your specific application needs, whether for engraving, cutting, or marking. | Ensures compatibility with your laser system. | Regularly assess application requirements. |

| 2. Consider Lens Coating | Choose lenses with appropriate coatings for better performance. | Increases efficiency and reduces reflections. | Clean with non-abrasive materials to protect coating. |

| 3. Evaluate Focal Length | Select the right focal length for your specific tasks. | Affects cutting speed and precision. | Store lenses in protective cases when not in use. |

| 4. Maintain Correct Lens Alignment | Ensure lens is properly aligned to reduce wear and improve performance. | Prolongs lens life and enhances cut quality. | Check alignment regularly during setup. |

| 5. Opt for High-Quality Materials | Use durable materials to ensure longevity. | Reduces the risk of lens damage. | Conduct visual inspections for scratches or cracks. |

| 6. Check for Compatibility with Your Laser | Ensure the lens works with your specific laser model. | Avoids performance issues and damage. | Refer to manufacturer's specifications before purchasing. |

| 7. Choose the Right Diameter | Select lens diameter that suits your application size. | Optimizes performance for different materials. | Avoid lens exposure to harsh elements. |

| 8. Regularly Clean Lenses | Keep lenses free from dust and debris. | Maintains optimal performance and clarity. | Use proper cleaning solutions and lint-free cloths. |

| 9. Inspect for Damage | Regularly check lenses for signs of damage. | Prevents unexpected failures during use. | Replace damaged lenses immediately. |

| 10. Store Lenses Properly | Use proper storage solutions to protect lenses. | Prevents damage from environmental factors. | Keep lenses in cases and away from direct sunlight. |