The demand for Optical Fiber Lasers continues to surge as industries seek more efficient and precise cutting, welding, and marking solutions. According to a recent market research report by ResearchAndMarkets, the global optical fiber laser market is projected to reach USD 5.9 billion by 2025, driven by advancements in technology and an increasing focus on automation. As industries diversify their requirements, selecting the appropriate Optical Fiber Laser becomes vital to ensure optimal performance and return on investment.

Industry expert Dr. Michael Hartmann, a renowned figure in laser technology, emphasizes the importance of making informed choices in this competitive landscape: "Choosing the right Optical Fiber Laser is not just a technical decision; it's a strategic one that can affect productivity, efficiency, and operational costs." This statement reinforces that understanding the features, capabilities, and intended applications of various Optical Fiber Lasers is crucial in today’s fast-paced manufacturing environment. As businesses navigate through the multitude of options available, the right selection can lead to significant gains in performance and cost-efficiency.

With this background, we present 10 essential tips to guide you in selecting the right Optical Fiber Laser tailored to your specific needs. Whether you are in automotive, aerospace, or electronics, aligning the laser technology with your applications will ensure you stay ahead in a rapidly evolving market.

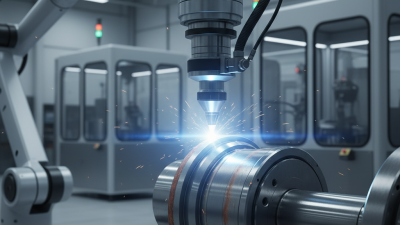

Optical fiber lasers have gained significant popularity in various industries due to their efficiency, precision, and versatility. Understanding the fundamentals of these lasers is crucial for making an informed purchasing decision. At their core, optical fiber lasers utilize optical fibers as the gain medium. This structure enables them to produce high-quality beams with excellent beam quality and stability. Additionally, they often require less maintenance than traditional lasers, reducing downtime and operational costs over time.

When choosing an optical fiber laser, consider the application it will be used for. If you need a laser for cutting materials, look for one with higher power capacity to ensure cleaner cuts. For marking and engraving, a model with optimal wavelength specifications can significantly enhance the clarity of the markings. Another essential tip is to evaluate the cooling system of the laser; efficient cooling can extend the lifespan of the device and improve its performance during prolonged use.

Furthermore, pay attention to the compatibility of the laser with existing equipment. It’s beneficial to assess whether the laser integrates well with your current technological setup to avoid additional costs on upgrades or adjustments. By understanding these basics and following these tips, you can select the right optical fiber laser tailored to your specific operational needs.

| Tip | Description | Considerations | Applications |

|---|---|---|---|

| 1. Understand Power Requirements | Select a laser with suitable wattage for your specific application. | Higher power increases cutting speed but may require more cooling. | Metal cutting, welding. |

| 2. Consider Beam Quality | Evaluate the beam's mode quality like M^2 for cutting precision. | A lower M^2 value indicates better quality. | Fine detail work, engraving. |

| 3. Evaluate Cooling Systems | Look for efficient cooling solutions to manage heat. | Water-cooled systems often offer better temperature management. | Long operations, high duty cycles. |

| 4. Assess the Required Cutting Surface | Choose a laser that matches the size of the materials you work with. | Consider if you need a large table or a compact machine. | Sheet metal cutting, frame structures. |

| 5. Factor in Material Types | Different lasers are better suited for materials like metal, plastic, or ceramics. | Be aware of compatibility and limitations. | Mixed material projects. |

| 6. Study the Control System | A user-friendly interface can drastically improve productivity. | Consider software compatibility and ease of learning. | Automation, design adjustments. |

| 7. Check for Maintenance Requirements | Regular maintenance can prolong laser life and performance. | Understand the tasks involved and frequency required. | Prolonged operation, production demands. |

| 8. Inquire about Safety Features | Look for lasers with built-in safety mechanisms and sensors. | Safety is paramount in a workshop setting. | Workshops, industrial settings. |

| 9. Analyze Total Cost of Ownership | Consider not just price but operational and maintenance costs. | Calculate the long-term investment return. | Budget planning. |

| 10. Seek Technical Support | Reliable technical support is crucial for troubleshooting. | Verify response times and availability. | Operational efficiency. |

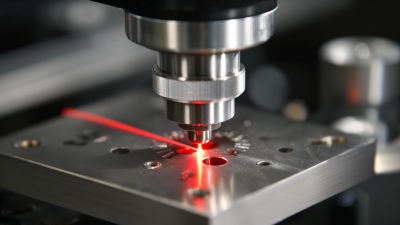

When selecting an optical fiber laser, identifying your specific application requirements is crucial. Different applications, ranging from industrial cutting and welding to engraving and 3D printing, demand varying specifications. According to a report by MarketsandMarkets, the global fiber laser market is projected to reach $5.2 billion by 2026, driven by the increasing adoption of these lasers across diverse sectors. Understanding the type of materials you’ll be processing and the thickness or density of these materials is essential, as it significantly influences the power and wavelength you’ll require.

For instance, if your application involves working with metals, a laser with a wavelength of around 1,070 nm will generally yield better absorption for metals than longer wavelengths. Conversely, for cutting or marking plastic, shorter wavelengths may be more effective. Furthermore, the production speed and precision needed for your applications should also guide your choice. A report by Fortune Business Insights reveals that precision manufacturing processes are often associated with fiber lasers due to their ability to produce fine cuts and intricate patterns without significant heat affected zones. Assessing these factors effectively ensures that you choose a fiber laser that not only meets your operational needs but also enhances productivity and cost-efficiency.

When selecting the appropriate optical fiber laser for your applications, evaluating power and performance specifications is crucial. The laser's power output directly impacts its cutting speed and material capability. For instance, a study by the International Laser Manufacturing Association (ILMA) suggests that lasers with a power of 1 kW can effectively cut through mild steel up to 10 mm thick, while those with 5 kW can handle up to 25 mm. This large difference highlights the need for precise matching of laser power with the intended material and thickness to optimize operational efficiency.

Additionally, examining the performance specifications such as beam quality, efficiency, and pulse duration is vital. Generally, the beam quality, denoted by the M^2 factor, indicates how well the laser can focus; a lower M^2 value signifies a better beam quality. Data from the Laser Institute of America (LIA) indicate that lasers with an M^2 value under 1.5 are more desirable for precise applications. Furthermore, understanding the efficiency of the laser system will affect operational costs; current reports show that high-performance fiber lasers can reach efficiencies above 30%, meaning more output for less energy input. This effective utilization of power not only reduces costs but also minimizes the environmental impact of laser operations, making it an essential consideration in the selection process.

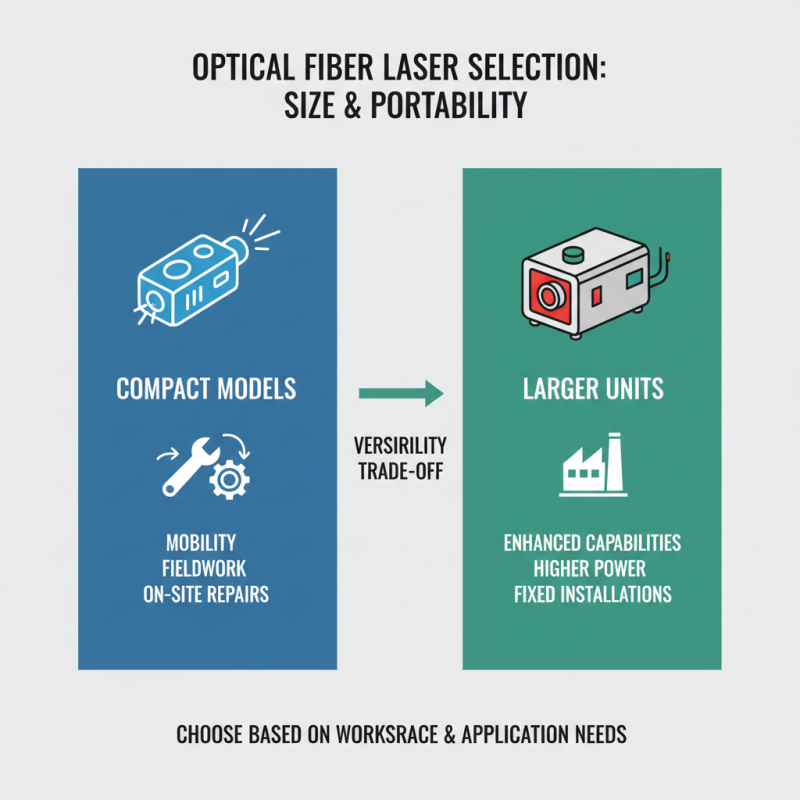

When selecting an optical fiber laser, size and portability are crucial factors that significantly impact its usability and versatility. Smaller, compact models are ideal for applications requiring mobility, such as fieldwork or on-site repairs, where moving equipment can be cumbersome. On the other hand, larger units might offer enhanced capabilities and power but could be less practical for environments where space is at a premium. Therefore, evaluating the physical dimensions and ensuring that the laser's size aligns with your workspace constraints is essential.

Maintenance needs also play a vital role in the decision-making process. Regular upkeep can cause downtime and impact productivity; therefore, opting for a system that is easy to maintain can save time and resources in the long run. Look for features that facilitate quick access to components and streamlined cleaning procedures. Additionally, consider the availability of replacement parts and technical support that can address potential issues efficiently, ensuring that your optical fiber laser remains in optimal working condition for years to come. Prioritizing size, portability, and maintenance will help ensure that the chosen laser aligns perfectly with your operational needs and enhances overall performance.

When selecting an optical fiber laser, one of the critical factors to consider is the reputation of the manufacturer. A reliable manufacturer often indicates a history of producing quality products and maintaining a consistent performance standard. Researching their background through customer reviews, industry rankings, and experienced users can provide valuable insight into the manufacturer’s capabilities. Look for feedback on aspects such as durability, efficiency, and ease of use, as these components are essential for achieving optimal performance in your applications.

Customer support is equally important in the decision-making process. A good manufacturer should offer robust support services, including installation assistance, maintenance guidance, and accessibility to technical support. Assess their response times and the availability of a knowledgeable support team, as prompt assistance can significantly reduce downtime in production scenarios. Additionally, consider if the manufacturer provides training resources and documentation to ensure you can effectively operate and troubleshoot the laser equipment. Overall, prioritizing a manufacturer with a stellar reputation and excellent customer support can enhance your experience and investment in optical fiber lasers.