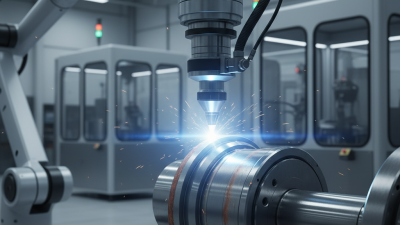

Choosing the right Laser Cladding Machine is a critical decision for businesses looking to enhance their production capabilities and improve the quality of their manufactured goods. With advancements in technology, laser cladding has emerged as a highly efficient process for applying metal coatings, increasing wear resistance, and repairing components without the need for extensive machining. As more companies recognize the benefits of this innovative technology, they face the challenge of selecting a machine that not only meets their specific operational requirements but also aligns with their long-term business goals.

In this guide, we will explore ten essential tips for selecting a Laser Cladding Machine that best suits your needs. From understanding the machine's specifications and capabilities to considering factors such as budget, application compatibility, and support services, these tips aim to equip you with the knowledge necessary to make an informed decision. By carefully evaluating these aspects, businesses can invest in a laser cladding solution that enhances efficiency, durability, and productivity, ultimately leading to greater competitiveness in their respective markets.

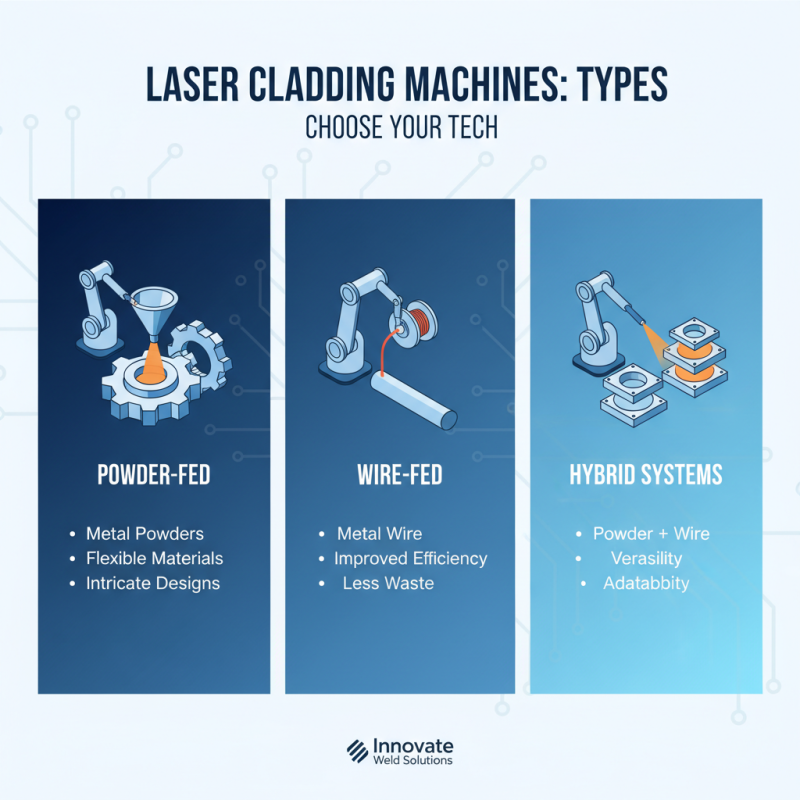

When it comes to selecting a laser cladding machine, it's crucial to understand the various types available to make an informed decision that aligns with your business needs. There are primarily three categories of laser cladding machines: powder-fed, wire-fed, and hybrid systems. Powder-fed machines utilize metal powders to build up layers, allowing flexibility in material choice and enabling intricate designs. Wire-fed machines, on the other hand, use a metal wire as the source material, which can improve efficiency and reduce waste. Hybrid systems blend both methods, offering the best of both worlds for companies seeking versatility and adaptability.

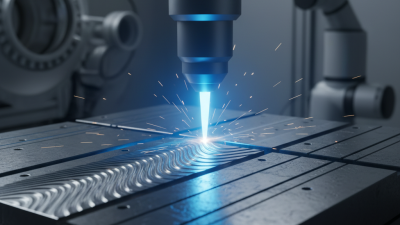

In making your choice, consider these essential tips: First, assess your specific applications and material requirements. Different industries may demand specialized options; for instance, if you’re working with complex geometries, a powder-fed machine might be the best fit. Second, evaluate the machine’s power output and laser type, as these factors influence the cladding speed and quality. Lastly, don’t overlook the importance of additional features such as automation capabilities and ease of maintenance, which can significantly impact your operational efficiency and productivity.

Choosing the right laser cladding machine is not just about the current demands but also future scalability. Ensure that the machine you select can grow with your business needs, allowing easy upgrades or modifications. By understanding the various types of machines and applying these tips, you can optimize your investment for sustained success in your operations.

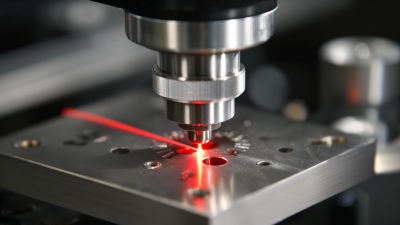

When selecting a laser cladding machine, understanding the technical specifications and performance metrics is crucial for optimizing operational efficiency and ensuring the longevity of equipment. Key performance indicators such as laser power, beam quality, and cooling systems play significant roles in determining the machine's capability. According to industry reports, a laser power of 1 kW to 10 kW is typically ideal for most applications, offering a balance between material deposition rate and precision. The beam quality, measured by the M² factor, should ideally be less than 1.5 for most cladding operations to ensure a focused and effective interaction with the substrate material.

One essential tip for businesses is to closely evaluate the machine's operational versatility. A machine that supports various materials and cladding processes can provide better return on investment and adaptability to changing demands. Additionally, pay attention to the automation features, as advanced systems often reduce operator error, enhance speed, and improve overall efficiency. Reports indicate that companies utilizing highly automated laser cladding systems can achieve up to 30% higher productivity compared to manual operations.

Furthermore, consider the machine's uptime reliability and maintenance requirements. Reliability metrics are essential for minimizing downtime and ensuring consistent production flow. Data shows that machines with robust maintenance tracking systems can reduce unexpected failures by as much as 25%. By assessing these technical specifications thoroughly, businesses can make informed decisions that align with their operational goals.

When it comes to selecting a laser cladding machine, evaluating pricing and budget considerations is crucial for your business's financial health. Start by establishing a clear budget that encompasses not only the purchase price but also installation, maintenance, and operational costs. This comprehensive approach helps prevent unexpected expenses down the line. Additionally, consider the return on investment (ROI) that the machine can deliver. A higher upfront cost may be justified by increased efficiency and reduced operational costs over time.

It's important to compare multiple options within your budget range. Look for machines that offer a good balance between features and cost. Investing in a machine with advanced capabilities might yield better results and longevity, ultimately saving you money in repairs and replacements.

Regularly review your pricing against market standards and future needs. Trends in technology can affect the value of laser cladding machines, so staying informed is essential. Consider leasing as an option; it can provide access to the latest technology without a significant initial outlay, allowing your business to adapt and innovate as needed. By doing so, you ensure that your spending aligns with your overall business strategy and goals.

When selecting a laser cladding machine, one of the most critical aspects to consider is the reputation of the manufacturer. A company with a strong track record often indicates reliability and quality in the products they produce. Researching the manufacturer’s history can provide insights into their experience, stability, and commitment to innovation. Look for manufacturers that have been in the industry for several years and have established themselves as leaders in technology and customer satisfaction. Testimonials and case studies from other businesses can also be invaluable in gauging their reputation.

In addition to reputation, robust support services are essential for ensuring the longevity and efficiency of your laser cladding machine. A good manufacturer should offer comprehensive technical support, including installation assistance, training for your staff, and readily available customer service. Prompt maintenance and repair services are also crucial; downtime can be costly in a business environment. Furthermore, a manufacturer that provides thorough documentation, user manuals, and training resources helps ensure your team is well-prepared to utilize the equipment effectively. By prioritizing manufacturers that excel in both reputation and support services, you position your business for long-term success in laser cladding applications.

| Tip No. | Tip Description | Manufacturer Reputation | Support Services Offered | Warranty Period |

|---|---|---|---|---|

| 1 | Evaluate the technology used | Highly rated for innovation | 24/7 technical support | 5 years |

| 2 | Check customer reviews | Positive feedback from users | On-site training and setup | 3 years |

| 3 | Analyze service contracts | Recognized service awards | Comprehensive maintenance package | 4 years |

| 4 | Assess product quality | ISO certified manufacturer | Remote diagnostics available | 3 years |

| 5 | Compare features and specifications | Consistently rated top in features | Customizable support plans | 5 years |

| 6 | Consider training options | Expert trainers available | Online resources and tutorials | 3 years |

| 7 | Look for technological advancements | Innovative designs and features | Annual software updates | 2 years |

| 8 | Evaluate delivery options | Timely delivery recognized | Fast-track shipping options | N/A |

| 9 | Inquire about spare parts | Excellent parts availability | 24-hour parts dispatch | 1 year |

| 10 | Request demo or trial | Live demonstrations praised | Trial periods offered | N/A |

When selecting a laser cladding machine for your business, it's crucial to focus on application-specific features that can significantly enhance performance and output quality. According to a report by MarketsandMarkets, the global laser cladding market is projected to grow to USD 1.83 billion by 2025, driven by the increasing demand for advanced surface treatment technologies in various industries, such as aerospace, automotive, and energy. Understanding the unique requirements of your application can help streamline this decision-making process.

The machine's power and wavelength are vital parameters, as they dictate the types of materials that can be processed and the thickness of the coatings achievable. For instance, different alloys require specific laser settings to ensure proper bonding and surface integrity. Additionally, the choice of nozzle design, cooling systems, and motion components must align with your operational needs to optimize cladding quality and productivity. Research highlights that machines designed with customizable operational features tend to minimize downtime and enhance operational efficiency, making them a more strategic investment in the long run. Understanding these facets can not only improve coating effectiveness but also reduce costs associated with repairs and maintenance over time.