In an era where material durability is paramount across various industries, the application of Laser Surface Engineering techniques has emerged as a transformative approach to enhance the performance and longevity of materials. This innovative process utilizes focused laser beams to modify the surface characteristics of materials, thereby improving their resistance to wear, corrosion, and fatigue. According to Dr. Emily Hughes, a leading expert in the field of Laser Surface Engineering, “The ability to tailor surface properties at a microscopic level opens up a new realm of possibilities for material science and engineering.”

As industries seek to optimize the lifespan and reliability of their products, the importance of advanced surface engineering methods becomes increasingly clear. Laser Surface Engineering not only addresses the intrinsic limitations of conventional surface treatments but also offers a precise, efficient, and versatile solution that can be customized to meet specific requirements. By harnessing the power of laser technology, manufacturers can achieve enhanced durability in materials, which is essential for maintaining competitive advantage in the market. This article delves into various Laser Surface Engineering techniques and their effectiveness in enhancing material durability, illuminating the pathway toward more resilient industrial applications.

Laser surface engineering techniques have emerged as pivotal methods for enhancing material durability across various applications. These techniques utilize concentrated laser beams to modify the surface properties of materials, resulting in improved wear resistance, corrosion resistance, and thermal stability. By precisely controlling energy input and focus, lasers can create microstructural changes within the surface layer, leading to superior performance compared to conventional treatments.

One notable approach is laser hardening, where the laser beam rapidly heats the surface to a predefined temperature, followed by immediate cooling. This process alters the microstructure, increasing the hardness of the material. Another technique, laser cladding, involves adding a new material onto the surface, which can significantly enhance its durability characteristics. The addition of alloying elements through laser cladding can create surfaces with tailored properties, making them more resilient to environmental stresses. Furthermore, techniques such as laser surface melting and alloying allow for the creation of custom surface layers that combine the benefits of different materials, providing targeted solutions for specific durability challenges.

Overall, laser surface engineering techniques present innovative solutions to improve material performance. By leveraging the unique capabilities of lasers, industries can extend the lifespan of components, reduce maintenance costs, and increase the reliability of their products in demanding applications.

| Technique | Material Type | Enhancement Effect | Application Areas |

|---|---|---|---|

| Laser Hardening | Steel Alloys | Increased surface hardness | Automotive, Aerospace |

| Laser Cladding | Various Metals | Improved wear resistance | Oil & Gas, Mining |

| Laser Surface Texturing | Plastics, Metals | Enhanced tribological properties | Electronics, Medical Devices |

| Laser Annealing | Silicon | Improved electrical properties | Semiconductors, Solar Cells |

| Laser Surface Melting | Titanium Alloys | Enhanced fatigue resistance | Aerospace, Biomedical |

Enhanced material durability is a critical advantage of employing laser surface engineering techniques. By applying high-intensity laser beams to the surface of materials, properties such as wear resistance, corrosion resistance, and mechanical strength can be significantly improved. The laser treatment modifies the surface microstructure, effectively increasing the hardness and toughness of the materials without compromising their overall integrity. This is particularly beneficial in industries where components are subjected to harsh conditions, as it prolongs the lifespan of machinery and tools, resulting in reduced maintenance costs and downtime.

Additionally, the benefits of enhanced material durability extend to environmental considerations. With longer-lasting components, the need for replacements decreases, which in turn reduces waste generated from manufacturing and disposal. Moreover, the enhanced performance of these materials often leads to improved efficiency in applications, thus contributing to energy savings. By investing in laser surface engineering, industries can achieve not only superior performance but also align with sustainability goals by minimizing their environmental footprint.

This chart displays the comparative durability of materials treated with different laser surface engineering techniques. Improved techniques like laser hardening and laser texturing significantly enhance the material's resistance to wear and tear, showcasing the benefits of advanced engineering processes.

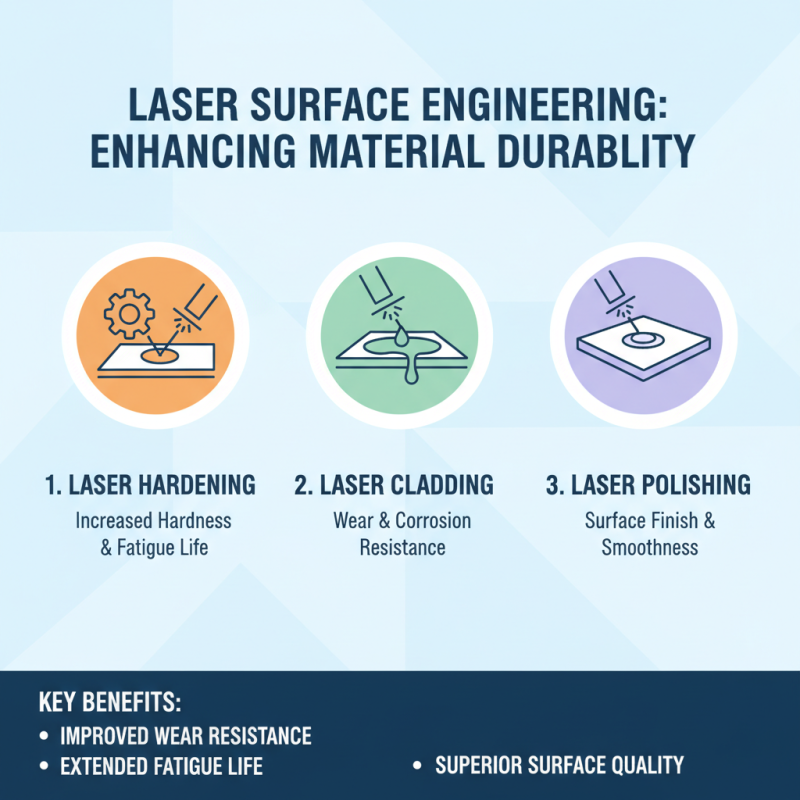

Laser surface engineering techniques have emerged as effective methods for enhancing the durability of materials. Among the key laser surface processing methods, laser hardening, laser cladding, and laser polishing stand out for their ability to improve wear resistance and fatigue life. Laser hardening involves using a focused laser beam to rapidly heat the surface of a material, followed by rapid cooling to alter its microstructure. This process can significantly increase the hardness and durability of the treated area without affecting the bulk properties of the material.

Laser cladding, another vital method, allows for the deposition of a new material layer on the surface, enhancing corrosion and wear resistance. This technique is particularly useful for repairing and extending the life of parts subjected to harsh conditions. Lastly, laser polishing uses high-intensity laser light to remove surface imperfections, resulting in a smoother finish that reduces friction and wear, thereby extending the material's lifespan.

Tips: When applying these laser surface engineering techniques, it's crucial to consider the base material's properties and the desired outcome. Ensure proper selection of laser parameters, such as power and scan speed, to achieve optimal results. Additionally, performing thorough pre- and post-treatment analyses can help in assessing the effectiveness of the processing method employed.

Laser surface engineering techniques are revolutionizing the industrial landscape by significantly enhancing the durability of materials. Industries such as aerospace, automotive, and manufacturing have recognized the value of integrating laser treatment processes to improve properties like wear resistance, fatigue strength, and corrosion resistance. According to a report by the International Journal of Advanced Manufacturing Technology, laser processing can increase the hardness of metals by up to 50%, making them better suited for demanding applications.

In the automotive industry, the implementation of laser-enhanced materials has led to substantial cost savings and performance improvements. The Steel Recycling Institute reports that the use of laser-treated advanced high-strength steels (AHSS) has resulted in lighter, more fuel-efficient vehicles while maintaining safety standards. Similarly, in aerospace, laser surface hardening techniques have been employed to extend the lifespan of critical components, with studies indicating that laser-treated components can endure operational stresses 30% longer than untreated counterparts.

Additionally, the renewable energy sector has begun to leverage laser surface engineering to enhance the durability of materials used in wind turbine blades and solar panels. A study published in the Journal of Renewable and Sustainable Energy highlighted that laser-treated composites exhibit superior resistance to weathering and mechanical fatigue, thereby improving the longevity and efficiency of renewable energy installations. These advancements underscore the growing importance of laser surface engineering in developing high-performance materials that meet the rigorous demands of modern industries.

The future of laser surface engineering holds immense promise in enhancing material durability across various industries. As technology evolves, we can anticipate advanced techniques that utilize high-energy laser beams to modify the surface properties of materials. These methods will not only improve wear resistance and fatigue strength but also foster the development of multifunctional surfaces that can withstand extreme environments. For example, innovations in pulse lasers and their applications could allow for more precise control over microstructural changes, leading to enhanced corrosion resistance without altering the bulk properties of the material.

Moreover, the integration of artificial intelligence and machine learning into laser surface engineering processes is set to revolutionize the field. By analyzing vast amounts of data, these technologies can optimize laser parameters in real time, facilitating greater customization of surface treatments. This capability will enable manufacturers to produce materials with tailored properties that meet specific durability requirements, ultimately resulting in longer-lasting products and reducing the frequency of replacements. As research progresses, we will likely see a surge in the application of laser treatments across sectors such as automotive, aerospace, and biomedical, paving the way for sustainable practices by extending the life cycle of key components.