In the realm of manufacturing, selecting the appropriate Powder Feeding System can significantly impact operational efficiency and product quality. As industry expert Dr. Jane Smith aptly stated, “A well-chosen powder feeding system is the backbone of consistent production and optimal performance.” The decision-making process involves understanding the specific needs of the production line, the properties of the powders being handled, and the overall system compatibility.

When assessing various options, manufacturers must consider factors such as precision, flow control, and adaptability to different materials. The right Powder Feeding System not only enhances productivity but also reduces waste and downtime, ultimately leading to a more sustainable manufacturing process. Building on Dr. Smith's insight, it is evident that investing time in selecting the most suitable system aligns with long-term goals and fosters continuous improvement within the manufacturing landscape.

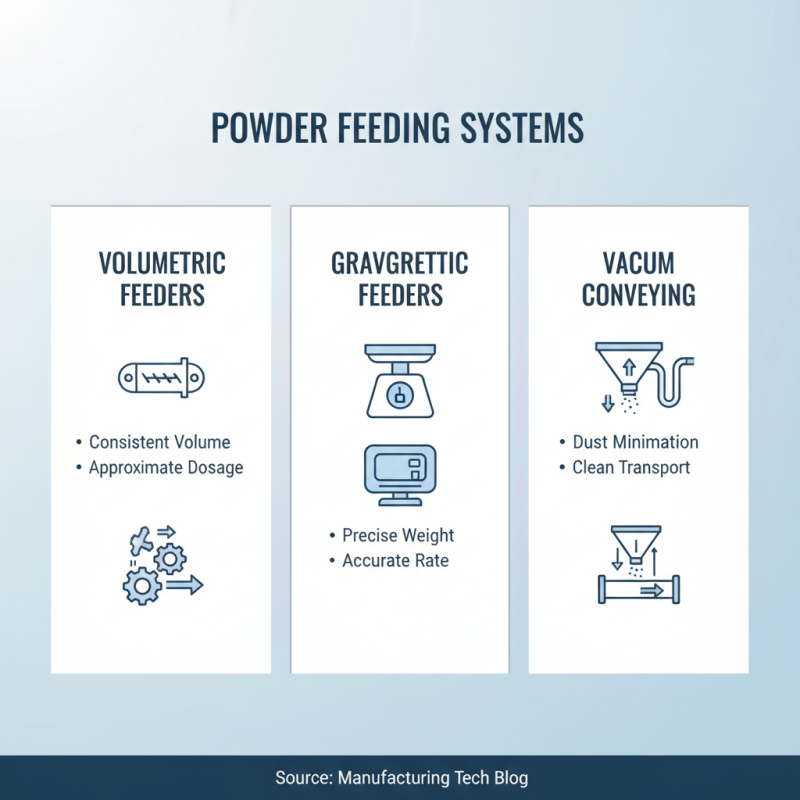

When selecting a powder feeding system for your manufacturing operation, it's crucial to understand the various types available. Generally, powder feeding systems can be classified into three main categories: volumetric feeders, gravimetric feeders, and vacuum conveying systems. Volumetric feeders deliver a consistent volume of material based on the speed of the feeder, making them suitable for applications that require approximate dosage. On the other hand, gravimetric feeders ensure accuracy by measuring the weight of the powder being dispensed, thus providing a more precise feeding rate. Vacuum conveying systems utilize suction to transport powder from one location to another, which is ideal for minimizing dust and maintaining a clean work environment.

Tips: When choosing a powder feeding system, consider factors such as the type of powder, required feeding accuracy, and the layout of your manufacturing space. Ensure that the system you select is compatible with the materials you handle, as certain powders may have unique properties that require specialized handling. Additionally, think about the ease of maintenance and cleaning of the equipment, as this can significantly impact operational efficiency.

It's also important to evaluate the scalability of the powder feeding system. As your production needs evolve, you may require a system that can adapt easily or be expanded. Look for systems that offer modular designs or allow for integration with other equipment in your manufacturing line. This foresight will help you avoid costly upgrades and disruptions in the future.

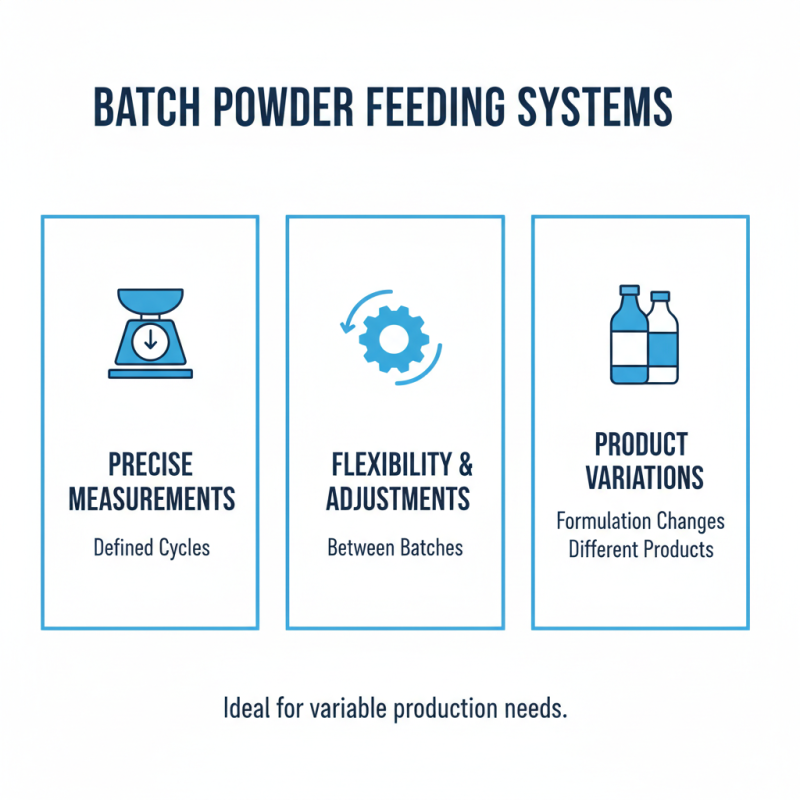

When selecting a powder feeding system for manufacturing purposes, it's crucial to evaluate whether a batch or continuous feeding system best suits your process requirements. Batch feeding systems are ideal for operations that require precise measurements of ingredients across defined cycles. This method allows for flexibility, as adjustments can be made between batches to enhance product consistency or to accommodate varying production volumes. Batch systems are particularly beneficial in scenarios where product formulations are frequently altered or when it’s necessary to run different products on the same equipment in sequence.

In contrast, continuous feeding systems provide a steady flow of materials, which can optimize efficiency in high-volume production environments. These systems are designed to maintain a constant input of powder, ensuring that downstream processes receive materials without interruption. This can lead to significant savings in time and resources, especially in operations where maintaining a uniform throughput is crucial. Continuous feeding may be more suitable for manufacturing processes that prioritize speed and uniformity over the flexibility to adjust formulations frequently. Evaluating the specific needs of your process will help in determining the most appropriate feeding method, influencing both production efficiency and product quality.

When selecting a powder feeding system, two critical factors come to the forefront: accuracy and capacity. Accuracy is essential as it directly impacts the quality and consistency of the final product. An imprecise feeding system can lead to variations in formulation, which may compromise product integrity or lead to additional waste. Choosing a system that offers high precision, such as gravimetric feeders or volumetric feeders with advanced control technologies, can help ensure that the exact amount of powder is dispensed each time.

Capacity, on the other hand, relates to the volume of powder the system can handle within a specific timeframe. This factor is particularly important for large-scale manufacturing operations where production demands can fluctuate dramatically. A system with a higher capacity reduces the need for frequent refills and ensures that production processes run smoothly without unnecessary delays. Evaluating the production scale and anticipated future needs will help in selecting a system that not only meets current demands but also accommodates potential growth, ensuring efficiency in the long run.

This bar chart displays the accuracy and capacity of three different powder feeding systems. Accuracy is measured in percentage, while capacity is measured in kilograms per hour. It helps manufacturers to compare and select the right powder feeding system according to their specific needs.

When selecting a powder feeding system for manufacturing, understanding the material properties, particularly flowability and bulk density, is crucial for optimizing performance. Flowability describes how easily a powder can move and fill a container, while bulk density provides insight into how much material is packed into a given volume. According to recent industry reports, materials with higher bulk density can lead to greater efficiency in feeding systems, allowing for reduced cycle times and improved consistency in production. For instance, a study from the American Institute of Chemical Engineers reported that powders with a bulk density above 0.6 g/cm³ often exhibit better flow characteristics, enabling smoother handling during processing.

Flowability is influenced by several factors, including particle size, shape, and moisture content. A study published in the International Journal of Pharmaceutics highlighted that irregularly shaped particles tend to have poorer flowability compared to spherical ones, often requiring additional modifications in the feeding system to ensure consistent flow rates. The flowability index can be quantified using various methods, including the Hausner ratio and Carr index, which provide essential insights that can guide manufacturers in selecting appropriate feed systems. By examining these material properties, manufacturers can make more informed decisions that enhance operational efficiency and product quality in their production processes.

| Material Type | Flowability (g/100g) | Bulk Density (kg/m³) | Recommended Feeding System |

|---|---|---|---|

| Fine Powder | 50 | 400 | Volumetric Feeder |

| Granules | 75 | 600 | Loss-in-Weight Feeder |

| Coarse Powder | 30 | 800 | Mechanical Feeder |

| Powder with High Moisture | 40 | 500 | Screw Feeder |

| Lightweight Powder | 60 | 350 | Coriolis Feeder |

When selecting a powder feeding system, a cost-benefit analysis is crucial to weigh the initial investment against long-term efficiency gains. The upfront costs can often be daunting, encompassing equipment purchase, installation, and personnel training. However, it’s essential to recognize that a quality powder feeding system can lead to significant savings over time. By investing in a system designed for precision and reliability, manufacturers can minimize material waste, reduce downtime, and enhance productivity.

In evaluating long-term efficiency, consider the system's ability to adapt to evolving production demands. Efficient powder handling can lead to improved product consistency and quality, which translates into reduced rework and rejects. Additionally, advanced systems often incorporate automation and monitoring features, allowing for real-time adjustments that optimize performance. While the initial costs may be high, the return on investment through increased operational efficiency, reduced labor requirements, and lower material costs can far outweigh these upfront expenditures. By focusing on the long-term benefits, manufacturers can make informed choices that support sustainable growth.