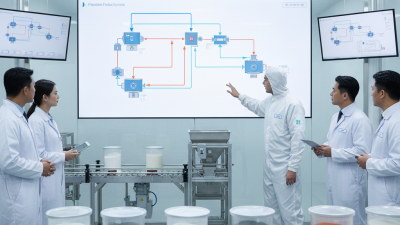

When it comes to optimizing production processes, selecting the right Powder Feeder is crucial for achieving efficiency and precision in material handling. As industries increasingly turn towards automation and advanced manufacturing techniques, the demand for reliable and effective powder feeding solutions has grown. The right Powder Feeder can drastically improve your workflow by ensuring consistent material flow, reducing waste, and enhancing overall product quality.

Understanding your specific application needs is essential when choosing a Powder Feeder. Factors such as the type of powder, required feeding rate, and environmental considerations play a vital role in the decision-making process. With various options available, it's important to evaluate the key features and specifications that align with your operational requirements. Whether you are in pharmaceuticals, food processing, or additive manufacturing, the appropriate Powder Feeder can make a significant difference in your production efficiency and product integrity.

By carefully assessing these elements and staying informed about the latest technologies, businesses can steer clear of common pitfalls and ensure they select the most suitable Powder Feeder for their unique applications. This guide aims to provide insights and considerations to help you navigate the options available and make an informed decision that will best serve your operational goals.

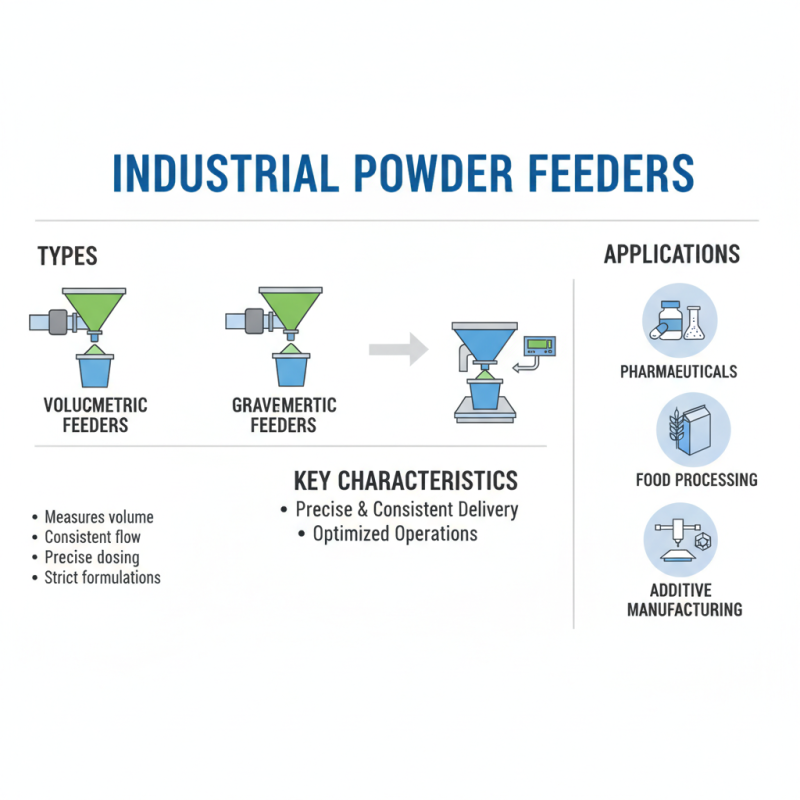

Powder feeders play a crucial role in a variety of industrial applications, particularly in processes that require precise and consistent delivery of powdered materials. Understanding the different types of powder feeders and their functionalities is essential for optimizing operations in sectors such as pharmaceuticals, food processing, and additive manufacturing. These feeders can be categorized into volumetric and gravimetric types, each serving specific needs based on the application. Volumetric feeders provide a consistent flow rate by measuring the volume of powder dispensed, making them suitable for large-scale production where precision is less critical. In contrast, gravimetric feeders utilize weight measurements to ensure accurate dosing, which is particularly important in applications that demand strict adherence to formulations.

Selecting the right powder feeder involves considering several factors, including material properties, flow characteristics, and the required feeding accuracy. For example, materials with poor flowability may necessitate a feeder with advanced agitation features to prevent clumping and ensure a uniform feed rate. Additionally, the feeder's integration capabilities with existing processes and control systems are vital for achieving operational efficiency. Understanding these elements allows manufacturers to choose a powder feeder that not only meets their specific application needs but also enhances overall productivity and quality in their operations.

When selecting a powder feeder for your application needs, several key factors must be considered to ensure you make the best choice. First, understanding the material being fed is crucial. Different powders have unique flow characteristics, particle sizes, and densities. For example, a cohesive powder may require a feeder that can handle variations in flow, while a free-flowing powder might need a different approach for precision dosing. Evaluating the physical properties of the powders helps in determining the necessary feeder type and configuration.

Another important factor is the required feeding rate and accuracy. Depending on the application, you may need a feeder that can deliver materials at a specific and consistent rate. This can influence the choice between volumetric and gravimetric feeders; gravimetric feeders typically offer higher accuracy by weighing the material as it is dispensed. Additionally, consider the ease of cleaning and maintenance. A feeder that is easy to disassemble and clean can save time and reduce contamination risks, which is particularly important in industries such as food, pharmaceuticals, and chemicals. By carefully assessing these factors, you can select a powder feeder that best aligns with your operational requirements.

When selecting a powder feeder, it’s essential to understand the various types available and their associated advantages and disadvantages. Gravity-fed feeders, for instance, are simple in design and can effectively handle a wide range of powder materials. Their primary benefit is ease of maintenance, as they typically feature minimal moving parts. However, they may struggle with fine powders or those that tend to clump, leading to inconsistent feeding rates.

On the other hand, auger feeders provide a reliable solution for more challenging materials. By utilizing a rotating screw mechanism, they can deliver precise quantities of powder with high accuracy. This makes them ideal for applications requiring consistent feed rates. Yet, their complexity means they can be prone to wear and may require more frequent maintenance. Additionally, auger feeders may not be suitable for highly abrasive materials due to wear and tear on the mechanism. Understanding these pros and cons can help businesses make informed decisions tailored to their specific application needs.

| Type of Powder Feeder | Pros | Cons | Best Applications |

|---|---|---|---|

| Volumetric Feeders | Simple design, cost-effective, easy to operate | Less accurate than gravimetric, affected by powder flow characteristics | Bulk powder handling, basic blending processes |

| Gravimetric Feeders | High accuracy, good for precise formulations | More expensive, complex design | Pharmaceuticals, fine chemicals, food processing |

| Pneumatic Feeders | Flexible installation, can handle a variety of powders | Requires compressed air, potential for powder degradation | Batch processing, pneumatic conveying systems |

| Loss-in-Weight Feeders | Very accurate, continuously monitors powder weight | Higher initial investment, requires calibration | Continuous production processes, high-precision applications |

| Screw Feeders | Effective for dense powders, customizable feed rates | Not suitable for all powder types, wear and tear issues | Chemicals, plastics, bulk solids handling |

When selecting a powder feeder for specific application needs, the compatibility of the equipment with the material being processed is paramount. Different powders, such as cohesive materials or those with varying particle sizes, can significantly impact the performance of the feeder. Studies show that powder characteristics—such as flowability and bulk density—should match the feeder design to reduce issues like clogging or uneven feed rates. For instance, a report from the American Institute of Chemical Engineers indicates that powders with a cohesion index over 20 may require precise handling techniques to ensure consistent feed.

Moreover, industry data reveals that the proper integration of powder feeders can enhance processing efficiency by up to 30%. This is particularly crucial in sectors like pharmaceuticals and food processing, where material characteristics are tightly regulated and must be handled delicately. Evaluation criteria for compatibility should include not only the physical properties of the powder but also the feeding mechanism and control systems of the feeder, ensuring they align with the specific flow dynamics needed for the application. By conducting a thorough analysis of these factors, users can optimize their powder feeding processes and maintain quality control effectively.

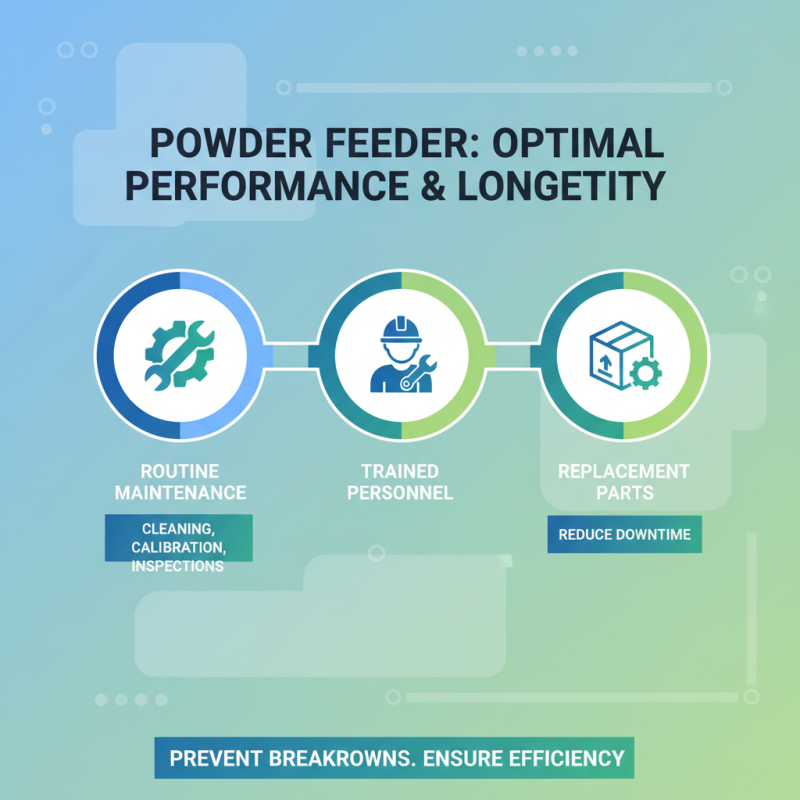

When selecting a powder feeder, maintenance and support considerations are crucial to ensure its longevity and efficiency in your application. Regular maintenance helps prevent unforeseen breakdowns, which can disrupt production and lead to costly downtime. It is essential to establish a routine maintenance schedule that includes cleaning, calibration, and part inspections. Properly trained personnel should carry out these tasks to ensure that the feeder operates at optimal performance levels. Additionally, choosing a powder feeder that comes with readily available replacement parts can significantly reduce lead times for repairs and keep operations running smoothly.

Support considerations also play a vital role in the long-term success of your powder feeding system. Evaluate the manufacturer's customer service reputation and the availability of technical support. Timely assistance can be invaluable when troubleshooting issues or when unexpected complications arise during operation. A reliable support network can provide you with access to training resources, operational manuals, and expert advice, which can enhance the overall performance and reliability of your powder feeder. Prioritizing these factors during the selection process will help you secure a functional and dependable powder feeding solution tailored to your specific needs.