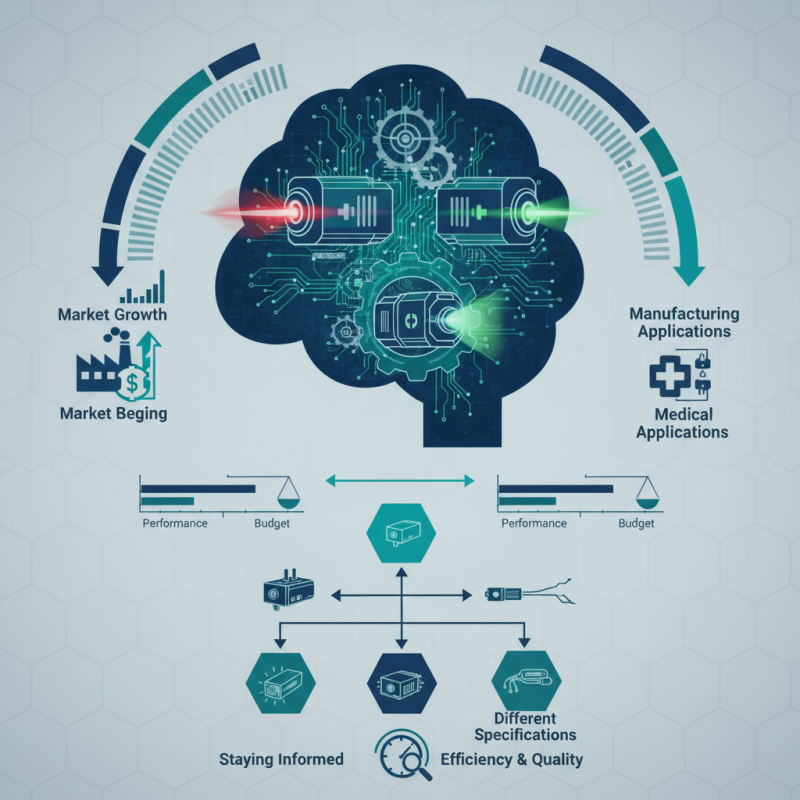

Choosing the right Laser Heads for your projects is crucial. The industry has seen a significant evolution in laser technology. Reports show a steady growth in the laser market, projected to reach $15 billion by 2026. These numbers reflect a rising demand for precision in manufacturing and medical applications.

Expert Dr. John Harper, a well-respected figure in the laser technology field, states, "Selecting the right Laser Heads can directly affect the outcome of your final product." His insights underline the importance of understanding specific requirements when choosing Laser Heads. Each application demands different specifications, from power output to wavelength.

Adapting to these needs makes decision-making challenging. It requires a balance between performance and budget. Users should consider their operational needs carefully. What works for one project may not suit another. The landscape is constantly changing, urging professionals to stay informed. A thoughtful approach to selecting Laser Heads can lead to significant advantages in efficiency and quality.

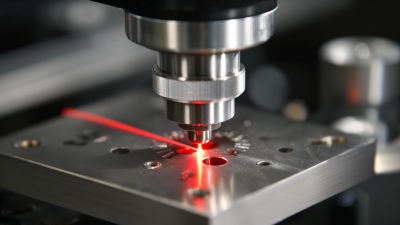

When choosing laser heads, understanding the different types available is crucial. There are CO2 laser heads, fiber laser heads, and diode laser heads. Each type has unique strengths. For instance, CO2 lasers excel in cutting and engraving non-metal materials, while fiber lasers are preferred for metals. According to a recent market report, the laser cutting market is projected to reach $4 billion by 2026, highlighting the growth and importance of selecting the right technology.

When considering your needs, evaluate the materials you will work with. CO2 heads are excellent for acrylic and wood, but not for metals. Fiber laser heads, on the other hand, can handle various metals with precision. The choice you make can affect both efficiency and cost.

Tips: Consider the wavelength and cooling options. Proper cooling can extend the lifespan of your laser heads. Remember, not all laser heads are created equal. Sometimes, specialized heads exist for niche applications, which can perform better but may require additional investment. Ensure to list your specific tasks before making a decision.

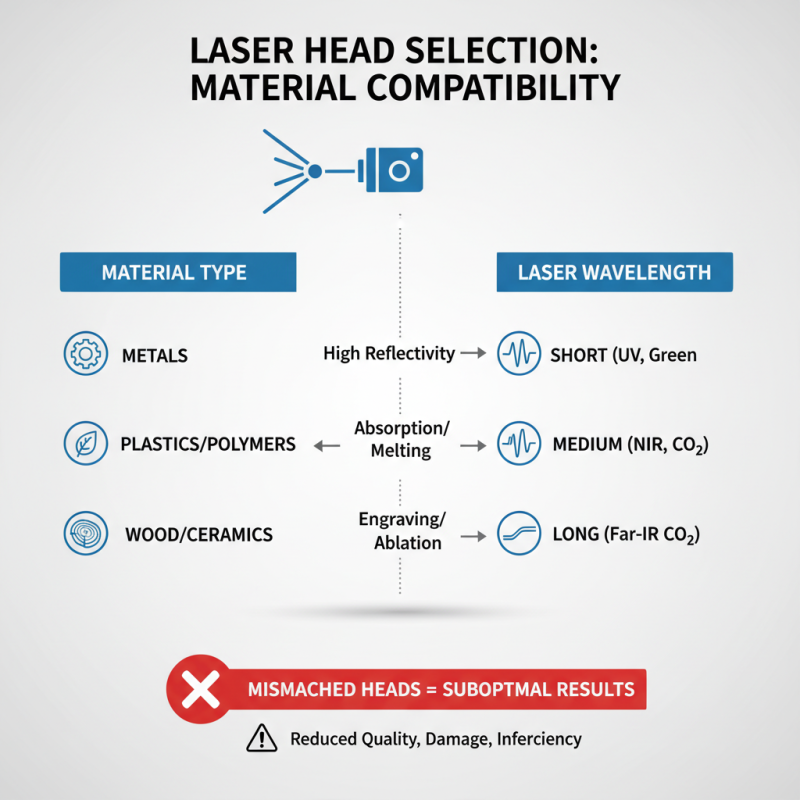

Choosing the right laser heads involves understanding your specific needs. Different applications require distinct laser wavelengths, powers, and focus capabilities. Industry data shows that around 70% of users experience setbacks due to improper equipment selection. This underscores the importance of aligning laser head specifications with your tasks.

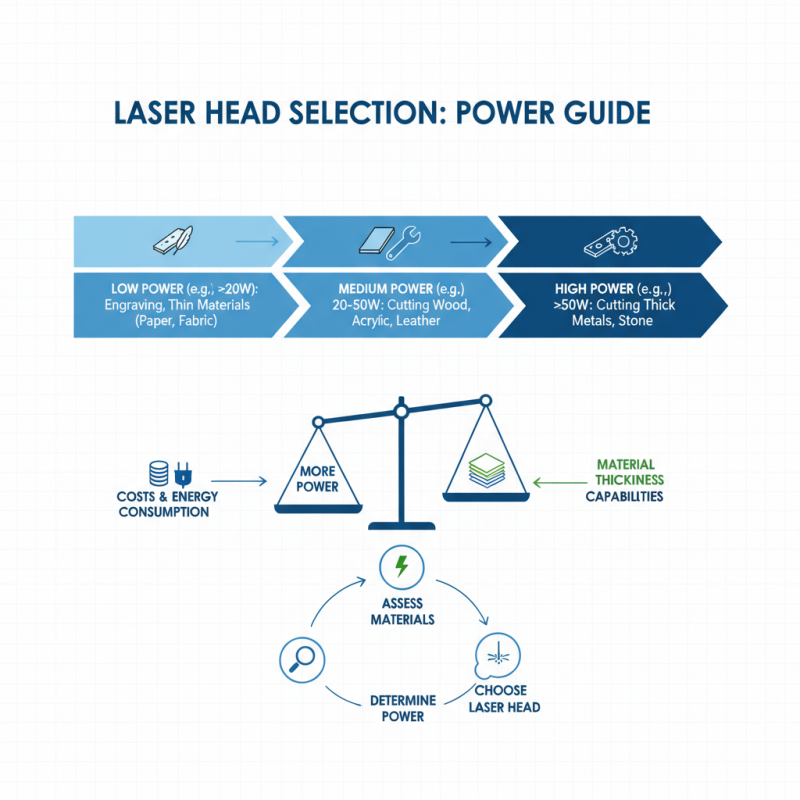

Power is a critical factor. Higher wattage may seem advantageous, but can lead to material damage or suboptimal results. For precision tasks, a lower wattage laser head could provide better control, minimizing errors. A recent report by industry analysts indicated that 45% of laser users faced challenges with overheating due to excessive power levels.

Material compatibility is another key consideration. Not all laser heads work with every material. For instance, metal fabrication often benefits from specific wavelengths, while plastics require different settings. Awareness of these nuances can save time and resources. Many choose based on price alone, but cheap alternatives can result in more significant long-term costs. The right choice requires thoughtful analysis and sometimes, trial and error.

| Application | Laser Type | Power Output (W) | Material Compatibility | Focal Length (mm) | Cooling Type | Cost ($) |

|---|---|---|---|---|---|---|

| Cutting | CO2 Laser | 100 | Wood, Acrylic | 50 | Water-Cooled | 3000 |

| Engraving | Fiber Laser | 20 | Metal, Plastic | 100 | Air-Cooled | 4500 |

| Marking | Diode Laser | 5 | Metal, Glass | 75 | Radiator | 2000 |

| Welding | YAG Laser | 50 | Metal | 100 | Water-Cooled | 6000 |

When choosing laser heads, material compatibility is essential. Different materials interact uniquely with laser wavelengths. A mismatched laser head can lead to suboptimal results.

Consider the type of material you plan to work with. Metals require different settings than plastics. The thickness of the material also affects performance. For intricate designs on wood, a specific laser head will yield better results.

Tips for choosing: always check the material’s laser compatibility. Conduct small tests to see how your materials respond. Sometimes, the results are not as expected. Reflection and adjustments might be necessary for the best quality.

Remember, it is not just about the specifications. User experience can be invaluable. Engage with others in the field to share insights. Mistakes can teach powerful lessons, guiding you toward better choices.

Choosing the right laser head begins with understanding power requirements. The power of a laser head influences its cutting or engraving capabilities. Higher power often means thicker materials can be processed more effectively. However, more power also means higher energy consumption, which can affect operational costs. Assess what materials you’ll work with regularly. That can guide your choice.

Efficiency is another important factor. An efficient laser head minimizes energy use while maximizing output. Analyze the design of the head. Some designs allow for quicker cooling or better energy transfer. If efficiency is low, it may lead to wasted time and resources. It’s essential to consider how often you plan to use the laser.

**Tips:** Always evaluate energy needs versus output. Consider regular maintenance. Sometimes, powerful heads require more upkeep. Also, test out different models if possible. Reflection on previous choices can lead to better decisions. A well-informed decision today can mean better results tomorrow.

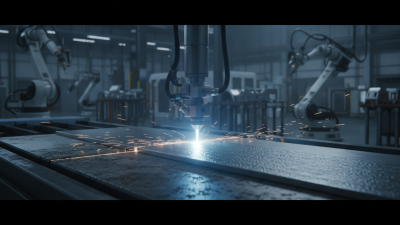

When considering laser heads, balancing cost and value is crucial. The initial investment can vary widely. Industry reports indicate that entry-level laser heads cost around $300, while high-end options can exceed $2,000. This range emphasizes the need for careful analysis. Knowing your budget helps narrow your choices down efficiently.

Tips: Focus on your specific needs. Determine the materials you will work with. Different laser heads perform better with various substrates. Understanding this can save you from costly mistakes.

Evaluating long-term value is essential. Sometimes, cheaper models lack durability. In a recent survey, 40% of users reported dissatisfaction with budget options, stating frequent maintenance issues. Opting for a slightly more expensive head may reduce long-term costs significantly.

Tips: Look beyond the price tag. Explore warranties and customer support. A reliable support system is worth the extra investment.