In recent years, "Laser Surface Finishing" has advanced significantly, becoming a key technology in various manufacturing sectors. Experts like Dr. Sarah Thompson emphasize its importance, stating, "Laser Surface Finishing enhances not just aesthetics but performance too." This technique offers precise control over surface properties, impacting durability and functionality.

The 2026 Best Laser Surface Finishing Techniques will highlight innovative methods that could redefine industry standards. Companies face challenges in achieving optimal results. For instance, inconsistencies in surface quality can lead to catastrophic failures. Leaders in the field must address these hurdles head-on as they explore new possibilities.

Looking forward, the integration of automation and AI in "Laser Surface Finishing" will likely transform this domain. However, relying solely on technology can overlook essential human insights. Balancing machine efficiency with skilled craftsmanship may be the key to unlocking the full potential of this technique. The journey toward perfecting these methods is ongoing and requires continuous reflection and adaptation.

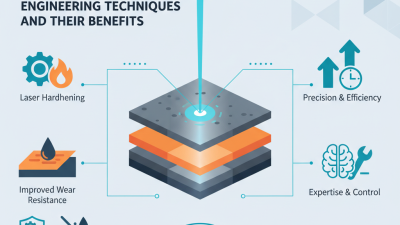

Laser surface finishing techniques have gained traction in various industries. They improve the properties of materials, including wear resistance and corrosion resistance. This technology is increasingly applied in aerospace, automotive, and medical sectors.

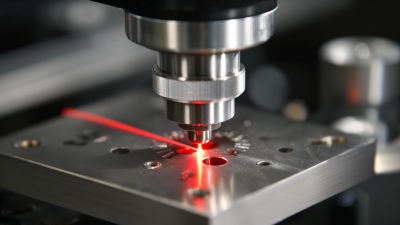

When using laser finishing, precision is key. Each technique has its strengths and limitations. For instance, while some can achieve very smooth surfaces, they might cause heat-affected zones. Users should be aware of these potential drawbacks before implementation.

Tips: Evaluate the specific materials you work with. Conduct tests to find the right laser settings. Automation can enhance consistency but may lack flexibility. Always review results critically and adjust processes as needed.

Laser surface finishing techniques are revolutionizing performance across various industries. These methods enhance surface characteristics by modifying top layers of materials. The incorporation of lasers leads to notable improvements in adhesion, wear resistance, and fatigue strength.

Performance metrics show significant gains when employing these techniques. For instance, some coatings exhibit a 30% increase in durability. This is crucial for applications in aerospace or automotive sectors. However, there remains room for improvement. The consistency of results can vary due to factors like material type and laser parameters.

Moreover, achieving the ideal finish may require a balance between speed and quality. A rapid process might compromise detail, while an overly cautious method can lead to inefficiencies. Understanding these nuances is key to optimizing laser surface finishing techniques for enhanced performance.

Laser surface finishing is transforming the materials processing industry. A comparative analysis reveals various techniques. These methods enhance performance across multiple sectors. According to recent reports, laser texturing improves adhesion by about 30%. It fosters better coating bonds and increases wear resistance.

Surface roughness significantly affects performance. Techniques like laser polishing and engraving refine surfaces. Laser polishing can reduce surface roughness by up to 50%. Moreover, engraving adds functionality and aesthetics to components. However, not every application benefits equally. Some materials may not respond well to laser treatments. A careful analysis is necessary.

Tip: Always test a small area before full application. Experimenting with different settings can yield better results. Consider your material’s unique properties. Understanding these nuances can help avoid unexpected outcomes. Additionally, stay updated on advancements in laser technology. They continue to evolve, offering new opportunities for enhanced performance.

| Technique | Material Type | Surface Roughness (Ra) | Processing Speed (m/min) | Cost Efficiency |

|---|---|---|---|---|

| Laser Polishing | Stainless Steel | 0.2 µm | 5 | High |

| Laser Ablation | Aluminum | 0.5 µm | 10 | Medium |

| Laser Engraving | Titanium | 1.0 µm | 8 | Medium |

| Laser Texturing | Polymer | 0.3 µm | 12 | High |

| Laser Annealing | Copper | 0.4 µm | 15 | Low |

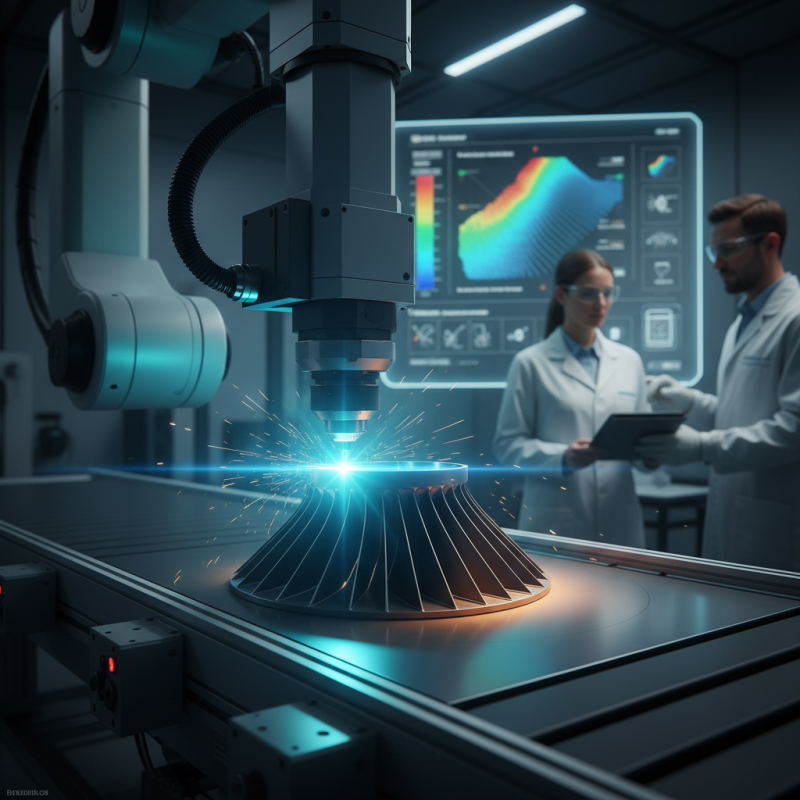

Laser finishing techniques have gained traction in aerospace and automotive sectors. These methods enhance surface quality and performance of components. Critical parts often require precision and durability, so laser treatment affords a way to meet these needs effectively.

In aerospace, the application of laser finishing is vital. It helps in reducing weight while maintaining strength. For example, fuselage parts, when treated with laser techniques, can become more efficient. This minimizes fuel consumption and increases overall aircraft performance. However, not all surfaces respond equally well to laser treatments. Materials such as aluminum can show varied outcomes, leading to inconsistent results that need further exploration.

The automotive industry, too, benefits from these technologies. Improved surfaces can lead to better fuel efficiency and prolonged lifespans of components. Yet, some defects might lie beneath the surface. Potential issues such as micro-cracking can arise with improper techniques. These challenges require ongoing research and feedback to optimize laser processing parameters. This continuous process will drive innovation and improve overall outcomes.

This chart represents various laser surface finishing techniques and their applications in the aerospace and automotive sectors, highlighting their effectiveness in enhancing performance.

Laser surface finishing is evolving rapidly, with innovations on the horizon. By 2026, expect to see techniques that enhance efficiency and precision. These advancements aim to improve material properties significantly. For instance, new laser types may offer better control over the finishing process. This promises finer details and less thermal distortion, making surfaces smoother.

Emerging technologies such as AI and machine learning are reshaping the landscape. These tools enable predictive analysis, optimizing finishing parameters in real-time. However, integrating AI needs careful consideration. It's crucial to ensure that machine decisions align with human expertise. Mistakes can happen if we rely solely on algorithms.

Sustainability is another key trend. Eco-friendly practices in laser finishing will likely gain traction by 2026. This could include efficient energy usage and minimizing waste. Yet, the challenge remains in balancing innovation and environmental responsibility. Every step toward greener processes requires thoughtful evaluation. The future of laser surface finishing is bright, yet it holds many complexities.