The landscape of Laser Repair is evolving rapidly. As industries seek efficiency, laser technology offers innovative solutions. A report from the International Society for Optics and Photonics states that the laser repair market is expected to grow by 15% annually over the next five years. This growth underscores the critical role of laser applications in manufacturing and maintenance.

Renowned laser technology expert Dr. Emily Carter emphasizes, "Proper techniques in Laser Repair can significantly reduce downtime and enhance productivity." Many companies still face challenges in adapting to these advancements. While the potential for improvement is clear, the implementation often reveals gaps in understanding and expertise.

Embracing new Laser Repair techniques requires ongoing training. It's essential to adapt these technologies to specific needs and workflows. Some firms overlook the significance of quality over speed. As laser repair techniques advance, it’s crucial to regularly assess their effectiveness and ensure they are implemented correctly for optimal results.

Laser repair techniques are evolving rapidly, offering innovative solutions for various industries. Understanding the basics is crucial. The technology primarily focuses on precision and efficiency. In 2020, it was noted that laser repairs reduced the need for extensive manual work by up to 45%. This efficiency can lead to significant cost savings.

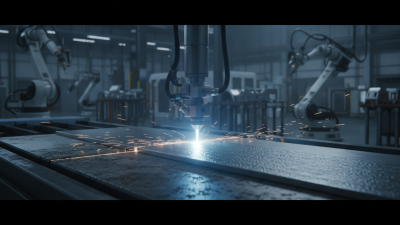

Different techniques exist within laser repair. For example, laser welding is widely used in metal repair. It provides strong bonds without distortions. However, the process can create heat-affected zones, leading to further complications. Data shows that 30% of laser welding failures arise from inadequate preparation. Precise control of laser parameters is essential to minimize errors.

Moreover, the integration of automation in laser repair is increasing. It enhances consistency and repeatability. However, not all facilities adopt this technology. The reluctance may stem from high initial costs or limited staff training. This gap highlights the need for ongoing education and investment in laser systems to maximize their potential. Embracing new techniques can seem daunting, but the benefits are substantial.

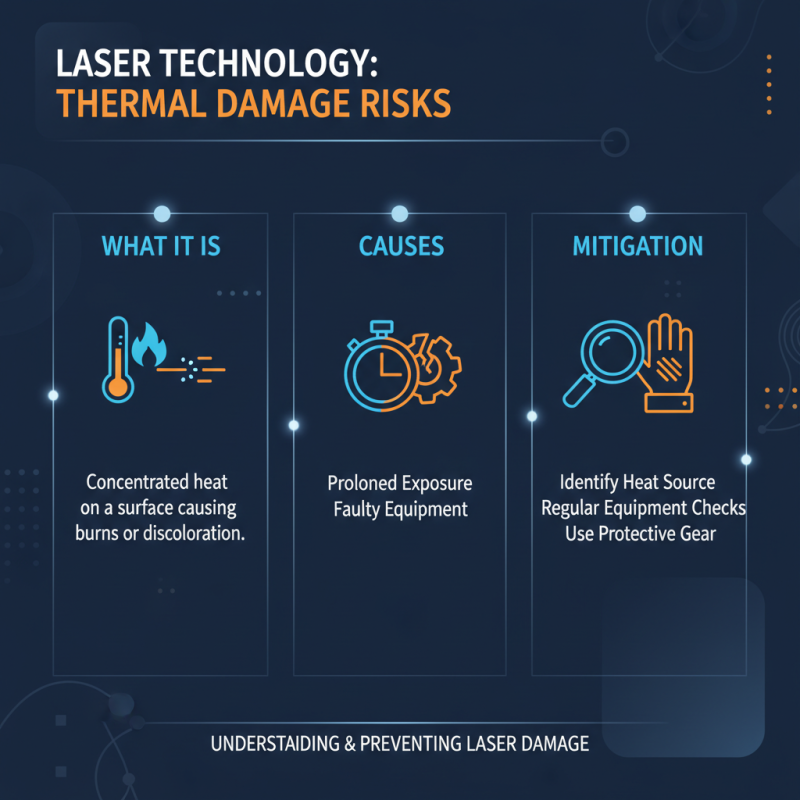

Laser technology has transformed various fields, but it comes with risks. Understanding common types of laser damage can help mitigate issues. One prevalent form is thermal damage. It occurs when heat is concentrated on a surface, leading to burns or discoloration. Identifying the source of excessive heat is crucial. Often, prolonged exposure or faulty equipment causes this problem.

Another type is optical damage. This involves damage to lenses or coatings due to incorrect laser settings. When power levels exceed the material tolerance, it can create cracks or distortions. Regular maintenance of equipment can prevent these issues, yet many overlook this vital aspect.

Mechanical damage also exists. This may appear as scratches or dents from accidental impacts. These imperfections can severely impact laser operations. Ensuring a secure workspace is paramount. However, accidents happen, and even minor neglect can lead to significant consequences. Understanding these damage types is essential for effective laser management. Reflecting on these aspects can improve safety and efficiency in laser applications.

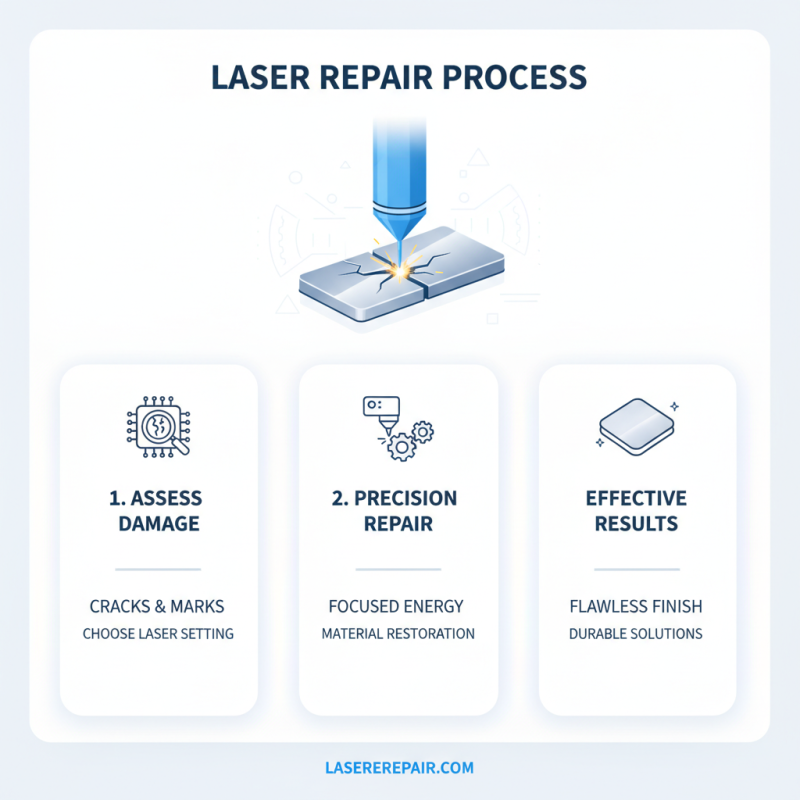

Laser repair offers precise solutions for various materials. Understanding the process is crucial for effective results. Begin by assessing the damage. Look for cracks or unwanted marks on the surface. This evaluation helps in choosing the right laser setting.

Next, prepare the workspace. Ensure it’s clean and well-lit. Remove any obstructions that might hinder the process. The laser equipment should be checked for functionality. Make necessary adjustments according to the material. Trial runs can help gauge effectiveness. It’s common to face challenges, such as improper alignment or incorrect intensity settings. Reflect on these issues to improve your technique.

During the repair, focus on technique. Move the laser at a consistent speed. This ensures an even surface. Pay attention to the reactions of the material. Sometimes, adjustments need to be made on the fly. It’s vital to remain patient and observant. Each repair can be a learning experience. Acknowledge mistakes and refine your skills over time.

Evaluating various laser repair techniques is essential for effective solutions. It is vital to consider the pros and cons before selecting a method. Some techniques focus on precision. They can provide excellent results but may require extensive training to execute correctly. Improper use can lead to poor outcomes or even additional damage.

Other approaches may prioritize speed. These can be attractive for quick fixes, yet they often compromise quality. Users might notice fading or uneven treatments over time. It's crucial to weigh immediate convenience against long-term results. Not every solution will suit every application, making careful reflection on the options necessary.

Considering the complexities of each technique is key. Reliable results come from understanding limitations. Some methods may not work well on certain materials. Ultimately, the best choice depends on specific needs and circumstances. However, the journey to finding the ideal laser repair technique involves trial, error, and a willingness to adapt.

| Repair Technique | Pros | Cons | Effectiveness Rating (1-10) |

|---|---|---|---|

| CO2 Laser Repair | Precise cutting, high efficiency | High energy consumption | 9 |

| Fiber Laser Repair | Better energy efficiency, lower cost | Sensitive to environmental conditions | 8 |

| Nd:YAG Laser Repair | Versatile material compatibility | Higher maintenance costs | 7 |

| Ultrashort Pulse Laser Repair | Minimal thermal damage | Expensive equipment | 9 |

| Laser Cladding | Excellent wear resistance | Complex process | 8 |

Laser repair technology is evolving rapidly. As we move toward 2026, several trends are shaping the future. One significant trend is the increasing use of AI in laser repair systems. AI can enhance precision and efficiency, minimizing human error. Automated systems will likely handle complex repairs, reducing costs and time for businesses.

Another trend is the development of portable laser technology. This advancement makes it easier to perform repairs on-site. Such convenience can improve service quality and customer satisfaction. However, portability may sometimes compromise power and effectiveness. It's crucial to assess the balance between convenience and performance.

Tips: Always keep your tools updated. Regular maintenance ensures optimal performance. Experiment with different techniques to discover what works best for you. Remember, not every solution fits every situation. Reflecting on past repairs can lead to better outcomes in future projects. Consider the potential limitations and workarounds when approaching new technologies.