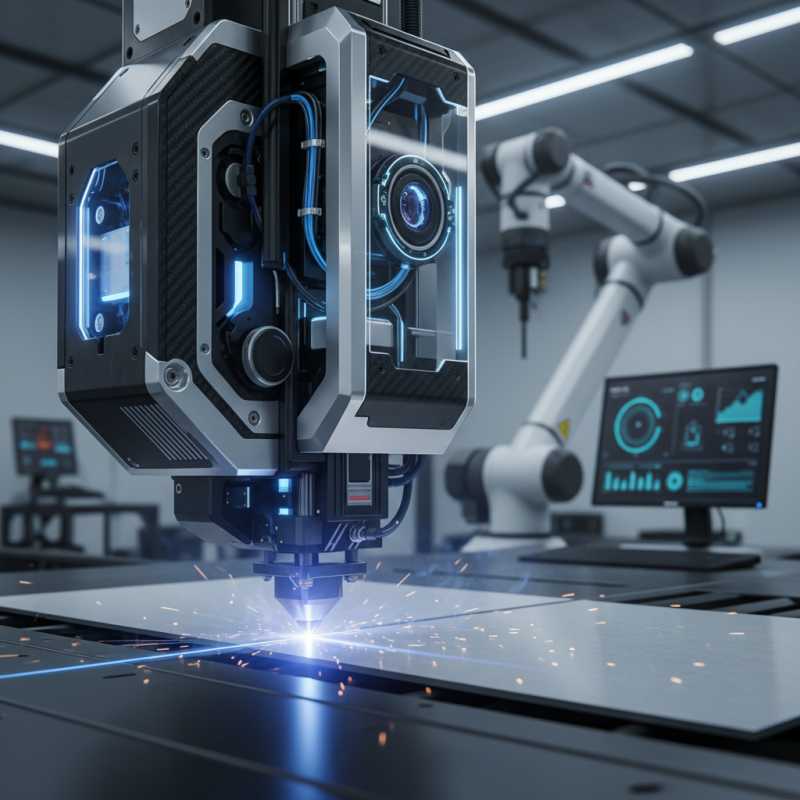

In the rapidly evolving world of manufacturing, Laser Heads play a crucial role in precision and quality. According to industry expert Dr. Emily Turner, "The right laser heads can transform an entire production line." This emphasizes the significance of selecting the best laser heads for specific applications.

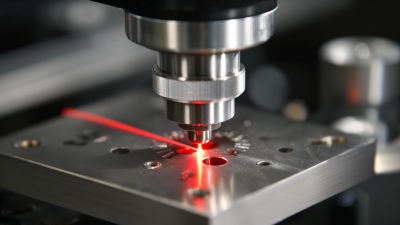

High-performance laser heads can enhance cutting accuracy and efficiency. For example, new models feature advanced cooling systems and improved optics. These elements are vital for maintaining consistent performance under demanding conditions. However, not all laser heads meet these standards. Some may struggle with precision or durability, leading to production delays.

Choosing the best laser heads is not just about specifications. It requires an understanding of the unique needs of each project. As technology advances, so do the challenges. Users must continually assess their equipment to stay competitive. Reflecting on past choices can provide valuable lessons for future investments.

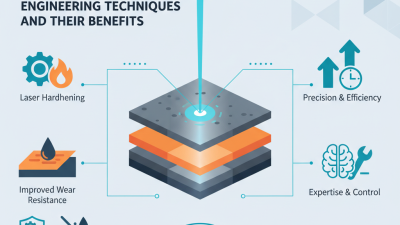

In 2026, laser head technology is evolving rapidly. Innovations are transforming precision performance in numerous industries. Recent studies highlight a 30% increase in accuracy due to advanced beam shaping techniques. These improvements allow for finer details and better quality in various applications.

The integration of AI-driven algorithms is another game-changer. These systems analyze real-time data, adjusting parameters instantly. Reports indicate that this technology reduces operational errors by up to 25%. However, reliance on automation raises concerns about potential malfunctions. Striking a balance between innovation and oversight is critical.

Moreover, cooling technologies are becoming more efficient. High-performance laser heads now feature better thermal management systems. This enhancement leads to prolonged lifespan and reliability. Yet, users must remain vigilant about these systems, as overheating can still occur. Continuous monitoring is essential to maintain optimal performance.

This chart illustrates the advancements in precision performance and quality metrics for various laser head technologies in 2026. The data represents key innovations that have been instrumental in improving precision across different laser head models.

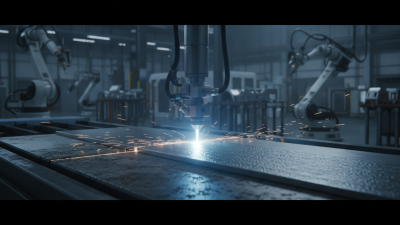

In the ever-evolving world of laser head manufacturing, brands are constantly pushing boundaries. This competition leads to rich innovations and high-quality products. Each brand brings unique features to the table. For instance, some emphasize speed, while others focus on precision. The choice often depends on the specific needs of industries, such as electronics or textiles.

When comparing industry leaders, it's essential to consider performance metrics. Certain brands may excel in fine-detail work, making them ideal for intricate designs. Others may provide robust solutions for large-scale manufacturing, but at times, they fall short in detail clarity. Users might find that a laser head that works well for one application does not perform equally in another. This inconsistency can be frustrating for those seeking reliable results.

Ultimately, choosing the right laser head requires careful thought. Reflecting on past experiences and performance is crucial. It's not merely about picking a name; it's about understanding specific needs. While many brands boast impressive technology, not all of them deliver equally. Users must weigh the pros and cons to find the best fit for their precision tasks.

| Dimension | Value 1 | Value 2 | Value 3 |

|---|---|---|---|

| Power Output (Watts) | 50W | 60W | 100W |

| Wavelength (nm) | 1064 | 532 | 355 |

| Cooling Type | Air-Cooled | Water-Cooled | Hybrid |

| Max Speed (mm/sec) | 300 | 500 | 700 |

| Precision (µm) | 30 | 25 | 15 |

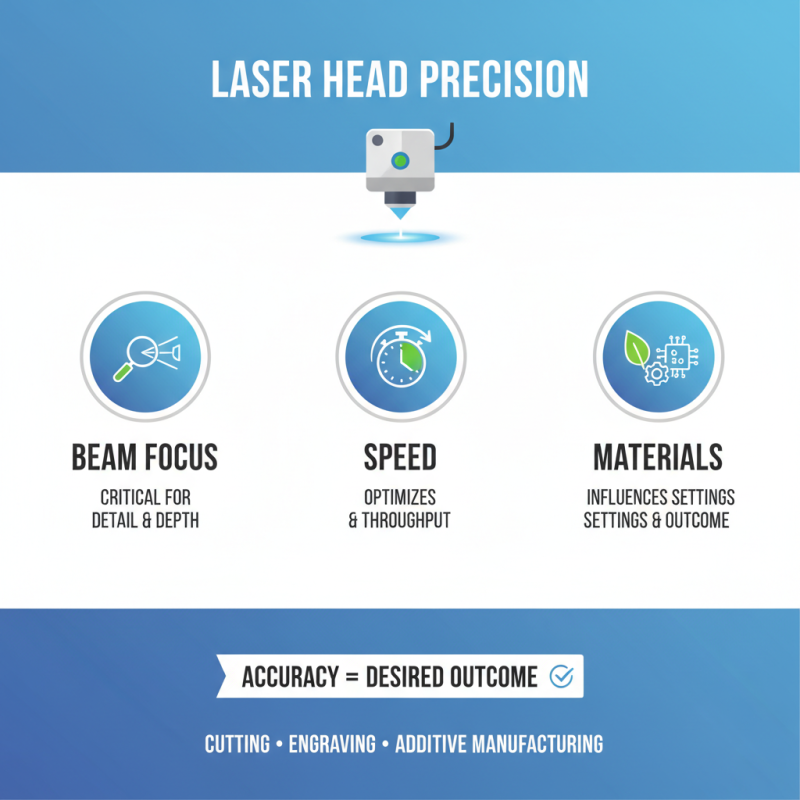

When evaluating laser heads, precision metrics are critical. Accuracy ensures the desired outcome in laser applications, be it cutting or engraving. A few key factors determine laser head performance. Beam focus, speed, and materials all play a role.

A laser's focus affects the quality of the cut or engraving. If the focus is off, results can vary significantly. Materials matter too. Different surfaces react to lasers in unique ways. Understanding these interactions is vital for achieving high precision.

Quality standards set the benchmarks for manufacturing laser heads. However, even with strict guidelines, variations can occur. This inconsistency can lead to frustration in projects. Therefore, continuous testing and adjustments are necessary. Users should not overlook maintenance either. Regular checks can enhance both accuracy and reliability of laser heads.

When choosing laser heads,

material compatibility is crucial.

Different applications require specific materials for optimal performance. A laser head designed for metals

may not work well with wood or acrylic.

Understanding the specific needs of your project can greatly influence the quality of your work.

For instance, a laser head configured for cutting thin materials often struggles with

thicker substrates. This can lead to uneven edges or incomplete cuts.

Proper selection helps avoid these issues, ensuring smooth finishes and precise engraving. Some materials can even

release harmful fumes when cut improperly, which is another aspect to consider.

Moreover, not all laser heads are created equal. Each type may have limitations when interacting with certain materials.

The ideal choice varies based on factors like thickness, density,

and texture. It’s essential to constantly assess performance and adapt as needed.

Experimenting with different settings is key, but it can sometimes lead to unpredictable results. This highlights the

importance of thorough testing before committing to a final design.

In 2026, the evolution of laser head technology promises significant advancements in precision performance and quality. As industries strive for unparalleled accuracy, the demand for high-performance laser heads is on the rise. Manufacturers are focusing on improving the materials used in fabrication. This often involves experimenting with innovative composites. These new materials aim to reduce weight while enhancing durability. Yet, achieving the perfect balance between strength and flexibility remains a challenge.

Market trends indicate a shift towards more compact designs. Smaller laser heads can be integrated into various machines without compromising functionality. However, miniaturization could lead to overheating issues. Keeping the temperature in check may require new cooling technologies that are still in development. The industry must navigate these complexities while maintaining cost efficiency. Simultaneously, smarter algorithms for focus adjustment are under exploration, although they require extensive testing.

A crucial consideration is sustainability. As awareness increases, manufacturers are pressured to adopt eco-friendly practices. This impact often clashes with performance goals, creating a dilemma. The journey towards an ideal laser head continues to reveal various hurdles. Each innovation brings its own set of questions and concerns. Balancing innovation with practical application will define the future of laser technology.