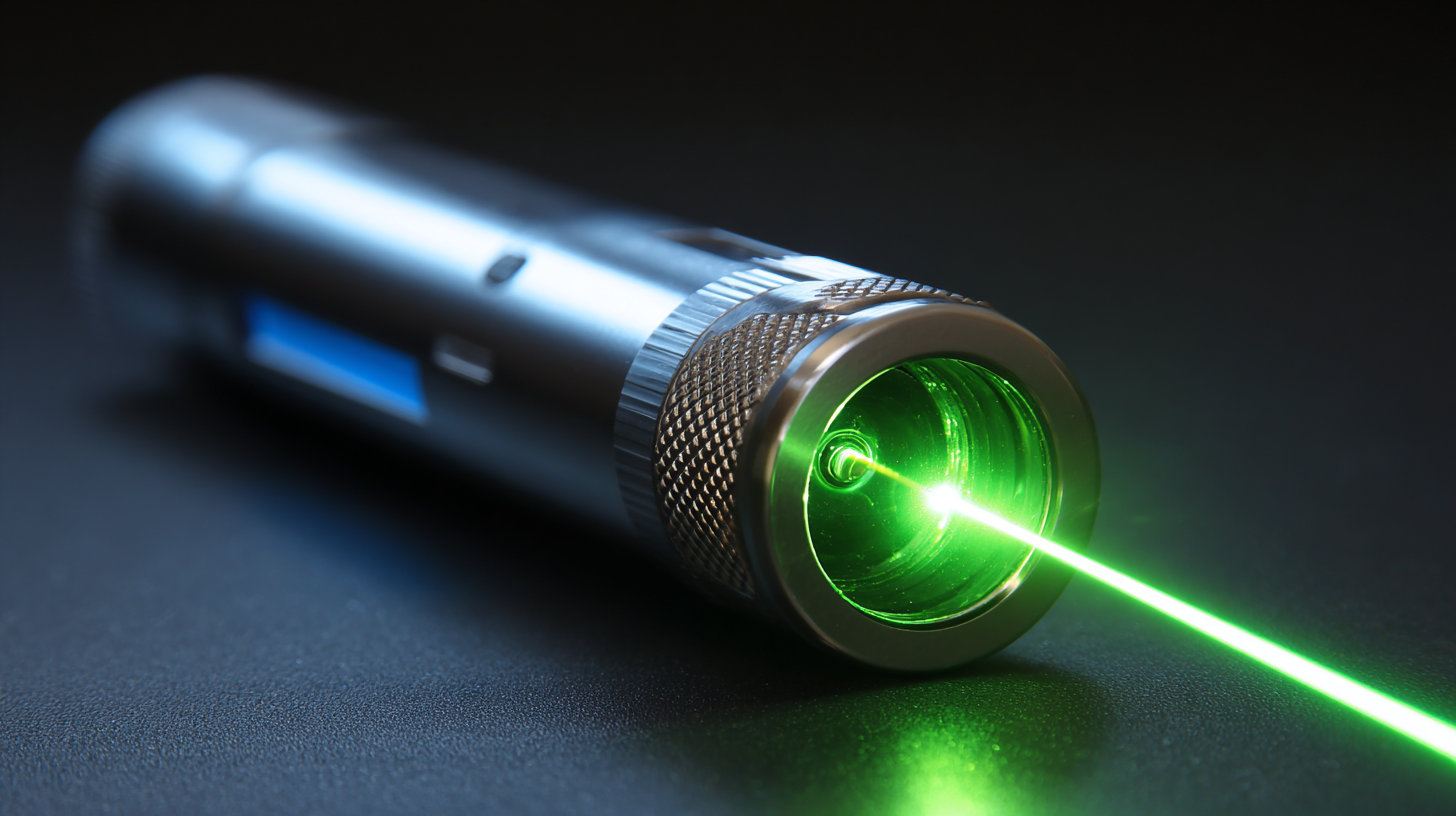

In the rapidly evolving landscape of laser technology, understanding the essential features of a Laser Head is crucial for achieving optimal performance in various applications, from industrial manufacturing to medical devices. According to a report by the International Data Corporation (IDC) from 2022, the global market for laser technologies is projected to reach $15 billion by 2027, highlighting the increasing reliance on high-performance Laser Heads. Industry expert Dr. Emily Carter, a leading researcher in laser applications, states, "The performance of a Laser Head can significantly affect the precision and efficiency of the entire system, making it imperative to consider its features closely."

As the demand for advanced laser solutions surges, it becomes vital for professionals to discern the specific characteristics that contribute to a Laser Head's effectiveness. Key aspects like power output, focusability, and cooling mechanisms play instrumental roles in enhancing performance and ensuring longevity. A thorough understanding of these features not only aids in making informed purchasing decisions but also promotes better integration into existing workflows. By delving into the ten most critical features of Laser Heads, this guide aims to equip industry professionals with the knowledge necessary to harness the full potential of their laser systems.

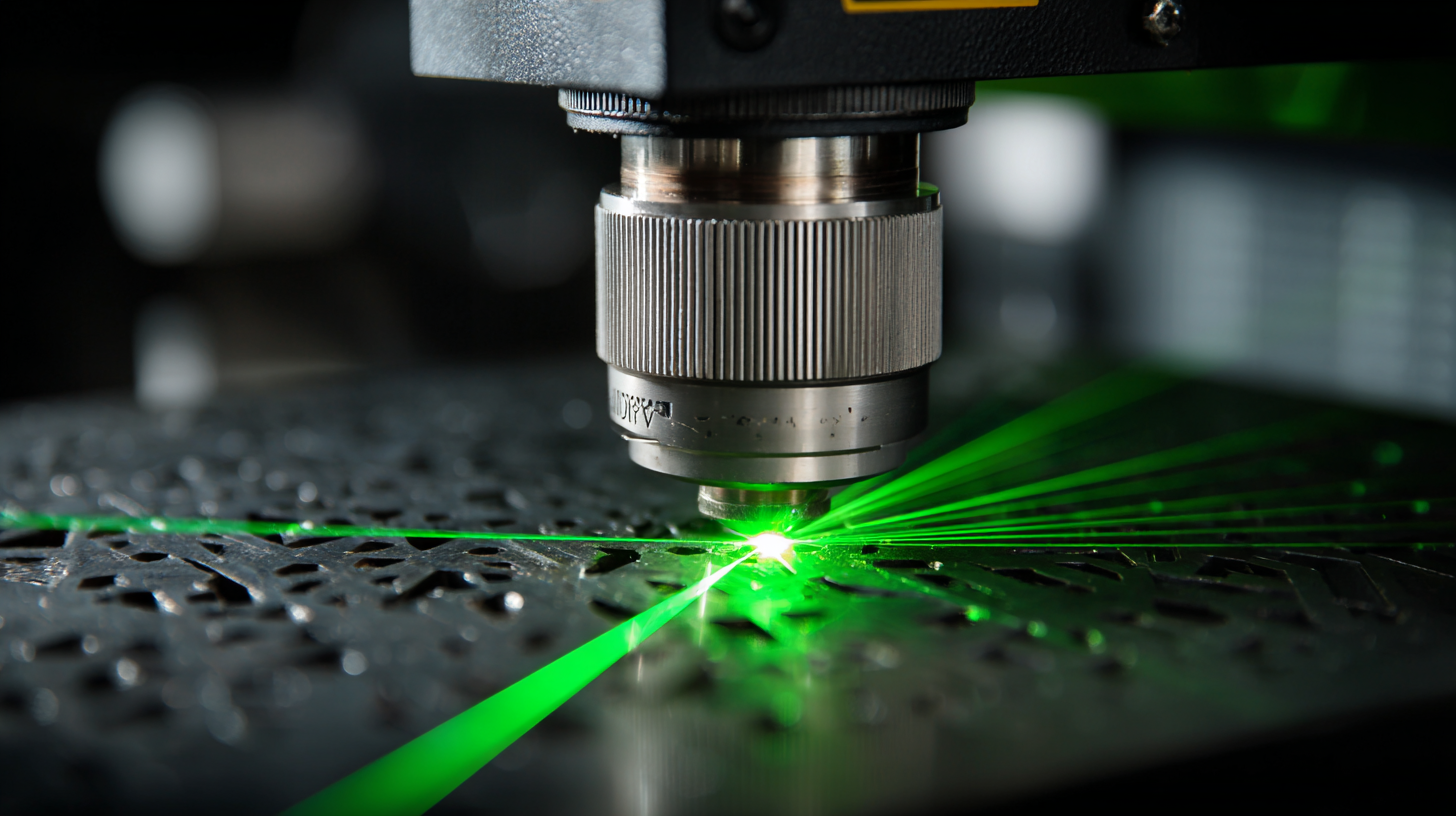

When it comes to industrial applications, the performance of laser heads is crucial in ensuring efficient operation and high-quality outputs. Key factors influencing laser head performance include beam quality, pulse duration, and stability. According to a report by the International Journal of Advanced Manufacturing Technology, a laser beam with a better quality factor (M²) typically yields superior cutting and engraving results, as it leads to a tighter focus and less energy dispersion. This is particularly important in industries such as aerospace and automotive manufacturing, where precision is paramount.

When discussing laser systems, one of the most critical factors influencing cutting precision is the selection of wavelength. Different materials respond uniquely to various wavelengths, which directly impacts the effectiveness of laser cutting processes. According to a report by the Laser Institute of America, optimizing the wavelength for specific materials can increase cutting speed by up to 40%, significantly enhancing productivity in manufacturing settings.

For example, CO2 lasers, operating at a wavelength of 10.6 micrometers, are highly effective for cutting non-metal materials like plastics and wood, while fiber lasers, with wavelengths around 1.06 micrometers, excel in processing metals such as steel and aluminum. Research published by the International Society for Optics and Photonics indicates that choosing a laser with the appropriate wavelength can minimize thermal distortion and improve edge quality, vital for applications requiring high precision.

Understanding these wavelength interactions allows engineers to tailor their laser systems to specific applications, ensuring optimal performance. With advancements in laser technology and growing demands for precision manufacturing, the ability to select the right wavelength is becoming an indispensable skill for industry professionals.

Cooling mechanisms play a crucial role in the longevity and efficiency of laser heads, influencing their performance in a variety of applications. According to a report by the Laser Institute of America, improper thermal management can lead to a reduction in operational efficiency by up to 30%. This efficiency loss results from overheating, which can cause the laser diodes to degrade rapidly, ultimately shortening their lifespan. By implementing effective cooling systems, such as liquid cooling or advanced air cooling methods, users can maintain optimal temperature levels and significantly enhance the lifespan of their laser equipment.

Moreover, a study published in the Journal of Applied Physics highlights that maintaining the optimal operating temperature for laser heads can improve their performance consistency. Laser heads that operate within the recommended thermal range exhibit a 20% increase in output power stability compared to those that are not properly cooled. Additionally, cooling mechanisms can reduce the risk of thermal lensing effects, which can distort the laser beam quality and lead to suboptimal results in precision applications. Adopting advanced cooling strategies not only bolsters the performance of laser heads but also ensures that they meet the growing demands of various industrial settings.

| Feature | Impact on Performance | Cooling Mechanism | Longevity (Hours) | Efficiency (%) |

|---|---|---|---|---|

| Wattage | Higher wattage increases cutting speed | Water-Cooled | 5000 | 92 |

| Beam Quality | Better beam quality leads to finer cuts | Air-Cooled | 4000 | 90 |

| Focus Lens Diameter | Larger diameter improves efficiency | Water-Cooled | 6000 | 95 |

| Cooling Efficiency | Effective cooling extends usage time | Liquid Cooling | 7000 | 96 |

| Reflector Material | High-quality materials enhance performance | Standard | 3000 | 87 |

| Operational Frequency | Higher frequency allows for rapid operations | Air-Cooled | 4500 | 88 |

| Durability Rating | Higher ratings indicate longer lifespan | Robust | 8000 | 93 |

| Maintenance Needs | Low maintenance ensures consistent use | Minimal | 3500 | 89 |

| Compatibility with Materials | Broader compatibility enhances utility | Standard | 5000 | 91 |

| Control Systems | Advanced control improves accuracy | Computer-Controlled | 6000 | 94 |

When selecting laser heads for diverse applications, material compatibility is paramount to achieving optimal performance. According to a report by the International Society of Optics and Photonics (SPIE), approximately 60% of laser processing failures can be attributed to incorrect material selection. Choosing the right laser head based on the material being processed, be it metals, plastics, or ceramics, ensures efficient energy transfer and less material damage, which is crucial for maintaining quality in production.

Different materials require laser heads with tailored features to maximize efficiency. For instance, a laser head designed for cutting aluminum will have distinct optics and cooling capabilities compared to one intended for acrylic, which melts differently under laser exposure. The Laser Institute of America (LIA) reports that using the appropriate wavelength for specific materials can increase processing speed by up to 30%, underlining the importance of aligning laser head specifications with material characteristics. Understanding the nuances of material compatibility not only enhances performance but also extends the lifespan of the equipment, leading to cost savings and improved production timelines.

Integrating advanced sensors into laser systems has revolutionized real-time performance monitoring, allowing for precise adjustments and improved outcomes in various applications. These sensors enable constant feedback, optimizing the laser's operational parameters to adapt to changing conditions. This functionality is particularly beneficial in industrial settings, where efficiency and accuracy are paramount. By leveraging data collected from these sensors, businesses can minimize downtime and enhance the quality of their outputs, making laser technology more reliable than ever.

Moreover, the trend toward smart technologies in laser systems aligns with broader movements in precision agriculture and environmental monitoring. Just as UAV-based detection and adaptive spraying techniques enhance crop protection, real-time monitoring in laser systems can lead to more sustainable practices across different sectors. The incorporation of these advanced technologies is not only paving the way for innovation but is also essential for businesses aiming to stay competitive in a rapidly evolving marketplace.