Laser Cladding Coating has emerged as a preferred method for enhancing the durability of various surfaces. This advanced technology provides an effective solution for industries facing wear and corrosion challenges. The process involves fusing a coating material onto a substrate using a focused laser beam. As a result, the surface benefits from improved hardness and resistance to harsh environments.

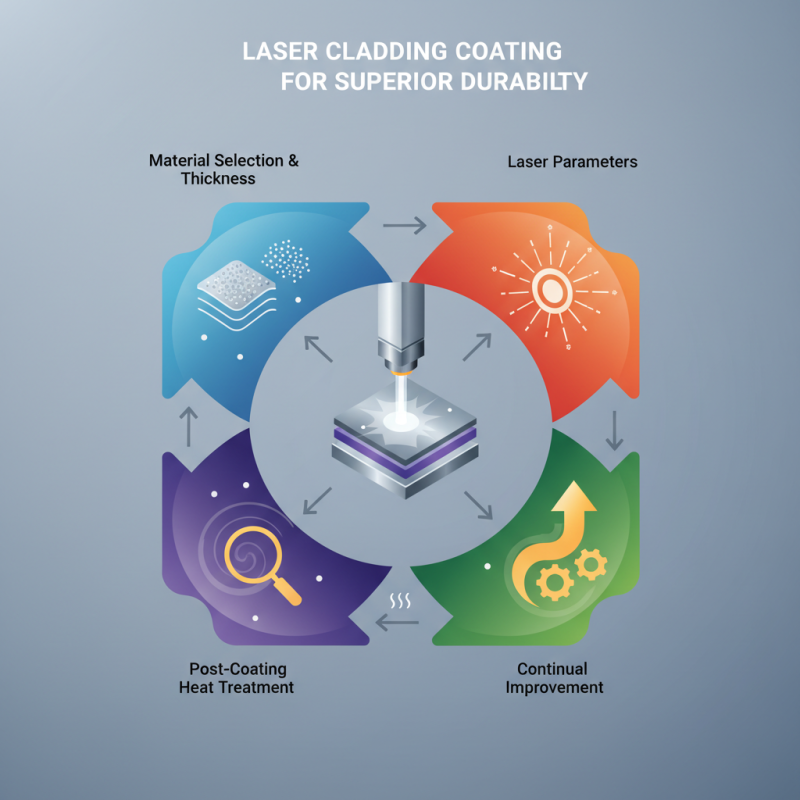

Yet, achieving superior durability through Laser Cladding Coating is not without its complexities. Factors such as material selection, coating thickness, and laser parameters demand careful consideration. Many practitioners overlook the impact of these elements on the final outcome. For instance, a too-thin layer may not provide sufficient protection, while an overly thick layer can compromise adherence.

Moreover, the post-coating process is equally critical. Proper heat treatment can enhance the mechanical properties of the coating. However, inconsistencies in this phase often lead to unexpected failures. Understanding these nuances is essential for optimizing the benefits of Laser Cladding Coating. Embracing a mindset of continual improvement will ultimately pave the way for enhanced performance and longer-lasting solutions.

Laser cladding coating is a revolutionary technique in materials engineering. It applies a layer of molten material to the surface of a substrate using a high-intensity laser. This method enhances resistance to wear, corrosion, and extreme temperatures. Industries are increasingly turning to laser cladding for improving durability in components like turbine blades and molds.

In practice, the effectiveness of laser cladding depends on several factors. These include material selection, laser parameters, and surface preparation. Often, achieving a uniform coating can be challenging. Inconsistent heat input may lead to defects such as cracks or inadequate bonding. Each application can vary drastically, making it crucial to tailor the process to specific needs.

The versatility of laser cladding applications is noteworthy. It allows for repairs on damaged components, extending their life significantly. Although promising, the technology is still evolving. Room for improvement remains in optimizing parameters for diverse substrates. The balance between speed and quality also requires further exploration. Only through ongoing research can we hope to unlock the full potential of laser cladding coating.

Laser cladding is gaining momentum in enhancing material durability. Specific materials play a crucial role in this process. Alloy powders, such as Stellite and tungsten carbide, are notable for their hardness and wear resistance. These materials enhance the cladding layer's ability to withstand abrasive conditions significantly. According to a report by the Materials Science Institute, alloy coatings can increase service life by 200% in severe environments.

Another key material is ceramic particles. They are incorporated to improve thermal stability and corrosion resistance. By embedding ceramics into the cladding layer, industries can achieve a balance between toughness and durability. Research indicates that ceramic-enhanced coatings can reduce maintenance costs by up to 30% over time. However, achieving the ideal mixture of ceramics can be challenging. Overuse may lead to brittleness, which is not desired.

Besides alloys and ceramics, nickel-based and iron-based materials are frequently used. These offer good adhesion and overall durability under high stress. Nonetheless, mixing different materials often presents compatibility issues. The right balance is essential. Achieving optimal durability with laser cladding requires careful selection and understanding of material characteristics. This process continues to evolve, with ongoing research revealing new insights and methodologies. The pursuit of superior durability remains a challenging yet rewarding endeavor.

| Material | Hardness (HV) | Corrosion Resistance | Wear Resistance | Applications |

|---|---|---|---|---|

| Inconel 625 | 200 | Excellent | High | Aerospace, Chemical Processing |

| Stellite 6 | 350 | Good | Excellent | Oil & Gas, Mining |

| H13 Tool Steel | 250 | Fair | High | Tooling, Molding |

| Titanium Alloy | 350 | Excellent | Moderate | Aerospace, Medical |

| Chromium Carbide | 1400 | Good | Excellent | Construction, Heavy Machinery |

Laser cladding is a sophisticated technique for enhancing the durability of component surfaces. This process involves applying a layer of material onto a substrate using a focused laser beam. According to a recent industry report, companies employing laser cladding can achieve a 30% increase in wear resistance. This is crucial for industries facing harsh operational conditions. The cladding material often consists of alloys or ceramics tailored to the environment.

The process begins with surface preparation. The substrate must be clean and sometimes pre-heated. Then, the laser melts the cladding material while simultaneously fusing it to the substrate. Precise control of the laser parameters is vital. A study indicated that inadequate settings could lead to poor bonding or even material cracking. This is a common pitfall, and many operators must regularly reassess their techniques. Next, once the material cools, post-treatment processes like grinding may be required to ensure a smooth finish.

Despite its advantages, laser cladding is not without its challenges. The need for precision makes it technology-intensive. Not all materials respond well to the laser process. For instance, some metals experience thermal stresses that lead to distortion. Continuous learning and adaptation are essential for those looking to master this technology. The evolving nature of materials science plays a significant role in improving techniques.

Laser cladding is a sophisticated process for improving coating quality and performance. It enhances durability through the precise application of material layers. The evaluation of these coatings is essential. A solid coating can resist wear and corrosion better than the base material. Inspecting adhesion is crucial. Poor adhesion leads to premature failure.

Coating thickness impacts performance significantly. Thinner coatings may wear out faster, while thicker layers can introduce residual stresses. These stresses can lead to cracking, reducing lifespan. Proper control of the laser parameters is vital. Temperature and feed rate must be optimized for the specific substrate. Small adjustments can lead to notable improvements.

Regular testing of coated samples offers insights into their long-term viability. Mechanical tests, like hardness and toughness assessments, provide a baseline for performance expectations. Visual inspections help detect inconsistencies. Dark spots or uneven color can indicate defects. Continual refinement of techniques is necessary to achieve optimal results. The journey toward superior durability involves ongoing evaluation and adaptation.

Laser cladding technology is evolving rapidly. Recent advancements suggest significant improvements in durability and performance. According to a report by MarketsandMarkets, the laser cladding market is projected to reach $1.85 billion by 2025, primarily driven by demand in aerospace and automotive sectors. This growth highlights the increasing reliance on laser cladding for superior wear resistance and corrosion protection.

Innovations are emerging, particularly in material composition. Researchers are exploring new alloys and ceramic composites, enhancing the capabilities of laser cladding. For instance, the use of nanostructured materials has shown promise, potentially increasing hardness by up to 30%. However, issues with adhesion and microstructural integrity remain prevalent. Achieving optimal conditions for laser cladding involves a delicate balancing act, as too much heat can lead to deformation.

Moreover, automation is on the rise in laser cladding applications. The integration of artificial intelligence can optimize parameters in real time. However, these technologies are not foolproof. Risks of process variability can still lead to inconsistent results. Continuous evolution in this field requires careful monitoring and adjustment to ensure the desired outcomes. The path to innovation is often fraught with challenges.