In today's fast-paced technological landscape, maintaining efficiency is vital. Laser Repair methods have emerged as an essential aspect of technology maintenance. These techniques offer precision and reliability for various equipment.

Laser Repair can significantly enhance the lifespan of expensive machinery. With advanced tools, technicians can address intricate issues that traditional methods often overlook. However, adopting new technology can be challenging. Many professionals face a steep learning curve.

It's crucial to analyze the effectiveness of these methods. Are they truly better than conventional repairs? Some users report mixed results, revealing a gap between expectation and reality. Understanding these nuances is essential for effective maintenance strategies in 2026.

Laser technology is critical in many industries. Yet, maintenance can be challenging. Studies show that 30% of laser equipment failures stem from improper maintenance practices. Businesses often overlook regular inspections, thinking they save time and money. However, neglecting routine checks often leads to costly repairs and downtime.

Effective laser repair techniques are essential for enhanced performance. Regular cleaning of optical components is vital. A recent report indicated that dirt and dust can reduce efficiency by up to 20%. Moreover, proper calibration can extend the lifespan of lasers significantly. Knowing when to replace parts is crucial. For instance, timely replacement of mirrors and lenses can prevent more severe damages.

Understanding the environment where lasers operate is equally important. High humidity or temperature fluctuations can lead to premature failure. Many facilities fail to monitor these factors, resulting in unexpected breakdowns. As technology evolves, staying updated on the best practices for laser maintenance is key. This proactive approach not only ensures operational efficiency but also maximizes the return on investment.

| Repair Method | Description | Estimated Cost | Expected Lifespan Extension | Frequency of Maintenance |

|---|---|---|---|---|

| Lens Cleaning | Regular cleaning of the laser lens to prevent debris buildup. | $50 | 6 months | Monthly |

| Alignment Calibration | Adjusting the laser components to ensure optimal performance. | $150 | 1 year | Bi-annually |

| Optical Component Replacement | Replacing worn-out optical components to maintain beam quality. | $300 | 2-3 years | Annually |

| Cooling System Maintenance | Servicing cooling systems to prevent overheating during operation. | $200 | 5 years | Quarterly |

| Software Updates | Installing the latest software to improve functionality and efficiency. | Free | Indefinite | Whenever available |

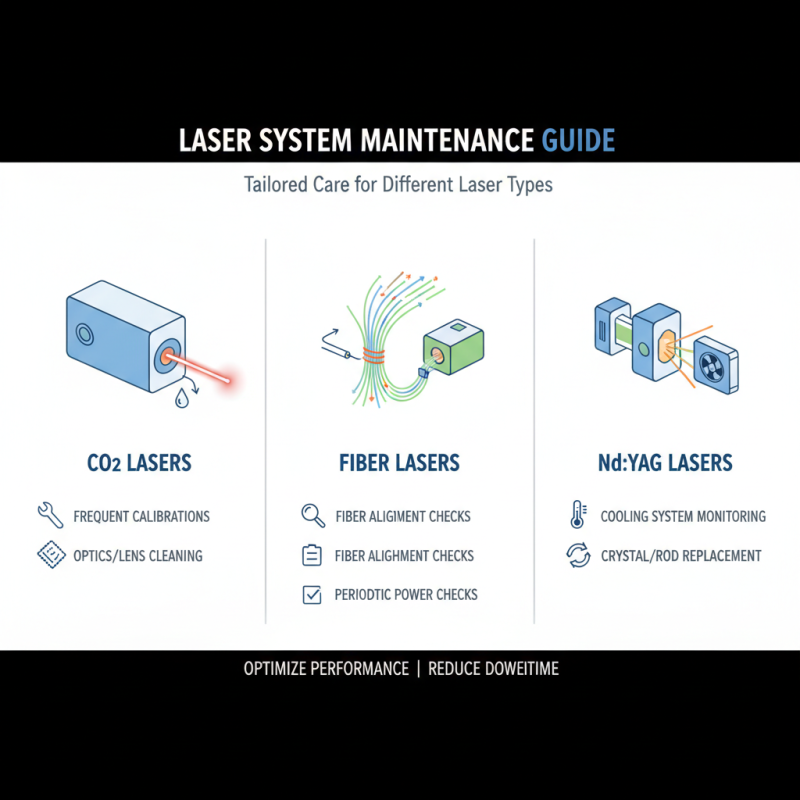

Laser systems are varied and complex. Each type has unique maintenance requirements. Some lasers need frequent calibrations, while others rely on regular cleaning. For instance, CO2 lasers often require lens cleaning to ensure optimal performance. Meanwhile, fiber lasers might need periodic checks on the fiber alignment.

Common issues can arise, impacting efficiency. Over time, dust can build up on critical components. This buildup often leads to decreased output quality. It’s essential to establish a regular maintenance schedule. Skipping maintenance can result in unexpected downtime. In humid environments, lasers can face additional challenges. Moisture can cause components to corrode and fail.

Understanding these systems helps users address specific needs effectively. It isn’t always clear what maintenance is necessary. Users may overlook early signs of wear. Regular training on maintenance practices could prove invaluable. Investing time in understanding the systems pays off in the long run. Proper care can dramatically extend the lifespan of laser equipment.

Diagnosing laser malfunctions can seem daunting. Start by checking the power supply. A loose connection may disrupt performance. Ensure that cables are intact and securely connected. Next, examine any error messages displayed on the device. These codes can provide critical insights. Sometimes, online resources or user manuals can clarify these codes.

Another common issue involves the laser beam quality. A distorted beam often indicates alignment problems. Carefully inspect the optical components for dirt or misalignment. A simple cleaning might help restore functionality. However, not all problems are obvious. Some may require thorough investigation and technical expertise.

It’s crucial to be prepared for tricky situations. Not every malfunction has an obvious cause. Documenting symptoms can assist in diagnosing the issue later. If repairs seem beyond your skills, don't hesitate to seek help. Consulting with experienced technicians can save time and frustration. Remember, maintaining laser equipment is an ongoing learning process.

This chart illustrates the efficiency rates of various laser repair methods in 2026. Each method has its own effectiveness percentage, showcasing the importance of choosing the right approach for maintenance.

Preventive maintenance is essential for laser technology. It reduces downtime and extends equipment lifespan. According to a recent study by the Laser Institute of America, regular maintenance can increase system performance by up to 30%. This can lead to significant savings in operational costs.

In laser systems, dust and debris can impact performance. Regular cleaning can mitigate these issues. It's recommended to conduct thorough inspections every month. Check lenses and mirrors for clarity. A simple cleaning can prevent major complications later. Most laser systems benefit from software updates as well. Keeping software current enhances security and performance.

Training operators is crucial. They must recognize early signs of malfunction. Quick responses can prevent larger repairs down the line. Data from industry reports indicates that well-trained staff can decrease repair costs by at least 25%. Yet, many facilities overlook this aspect. Regular training sessions should be prioritized. Reflecting on current practices can reveal gaps that need to be addressed.

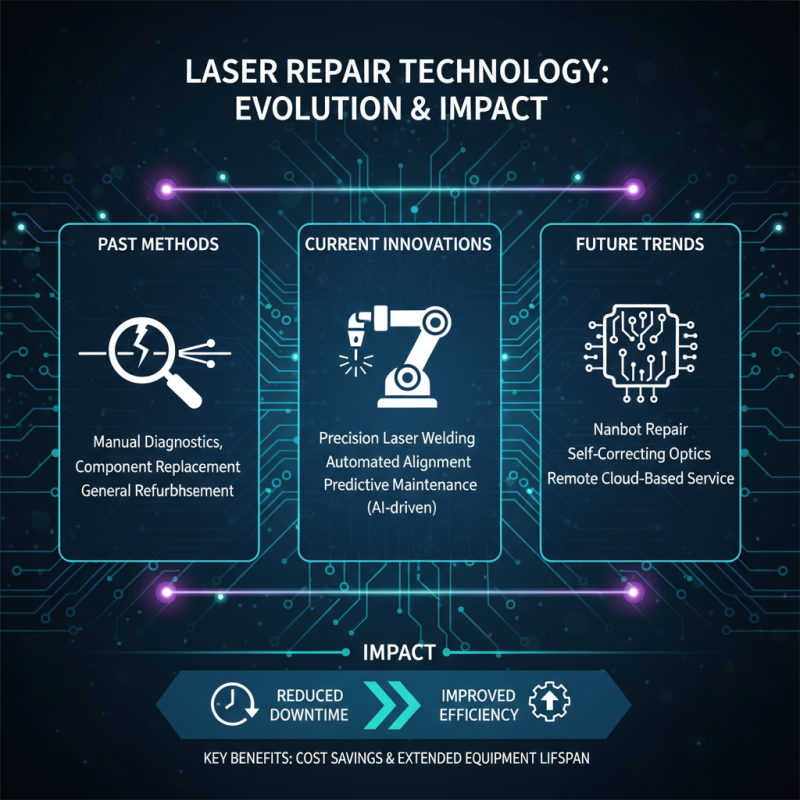

Laser repair technology is evolving rapidly. New innovations are changing how we maintain and restore laser equipment. Understanding these trends is crucial for improving efficiency and reducing downtime.

One significant trend is the adoption of advanced diagnostics. Tools that diagnose issues in real-time can save time. They highlight problems before they escalate. Consider investing in training for your team to use these diagnostic tools effectively. Remember, not every system is the same. The learning curve can be steep.

Another emerging innovation is predictive maintenance. This approach uses data analytics to foresee failures. It allows maintenance teams to act proactively. However, the data can be overwhelming. Regularly refining your data analysis processes is essential. Don't rely solely on technology; human insight is still valuable.

Lastly, remote repair capabilities are gaining traction. Experts can troubleshoot issues from afar, minimizing travel costs. However, ensure you have robust cybersecurity measures in place. Unsecured systems can lead to vulnerabilities.

Implement these tips steadily. Embrace innovation while reflecting on what works best for your environment. This balance will lead to improved efficiency and reliability in laser repair.